DeepTriDrill -Die Knock pin hole – MCTR

IMPROVED PRODUCTIVITY AND TOTLA COST

DeepTri drill Increased drilling productivity and cost reduction in drilling operations.

Tested against SS400 and high-speed steel drills, the DeepTri-Drill achieved favorable results despite the presence of long chips.

When applied in a vertical machining center on stainless steel material, the tool showed a threefold increase in table feed rate compared to competitors.

This performance not only enhances productivity but also leads to an overall cost reduction in the drilling process.

The combination of Tungaloy’s high-quality insert TOHT070304R-NDL AH725 and optimized cutting conditions contributes to these outstanding results.

Share

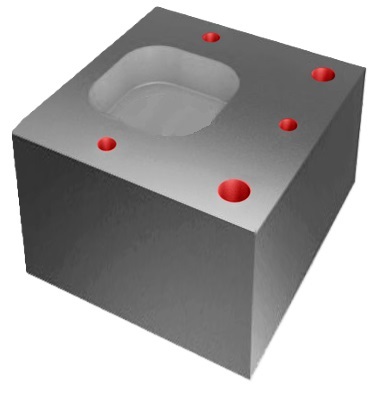

| Industry | Die & Mold |

|---|---|

| Component | die Knock pin |

| Material ISO code |

|

| Work material | SS400 |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Holemaking |

| Tool category | Deep hole drilling |

| Product name | DeepTri-Drill |

| TSR No. | 5162D |

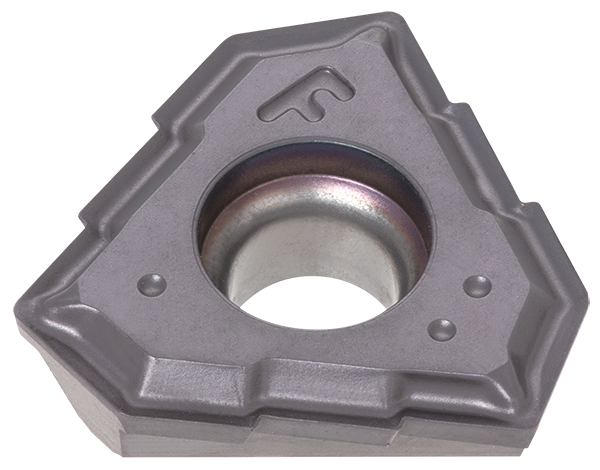

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | MCTR14.50XM25-15 | |

| Insert | TOHT070304R-NDL AH725 | HSS drill coated |

| Grade | AH725 | HSS + coating |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 14.5 | 14.5 |

| Hole depth H (mm) | 160 | 160 |

| Cutting speed V/c (m/min) | 80 | 14 |

| Feed f (mm/rev) | 0.08 | 0.17 |

| Feed speed Vf (mm/min) | 140 | 52 |

| Coolant | emulsion | emulsion |