BTA – Gas Turbine Upper Case – FINE BEAM

IMPROVE PRODUCTIVITY AND TOOL COST

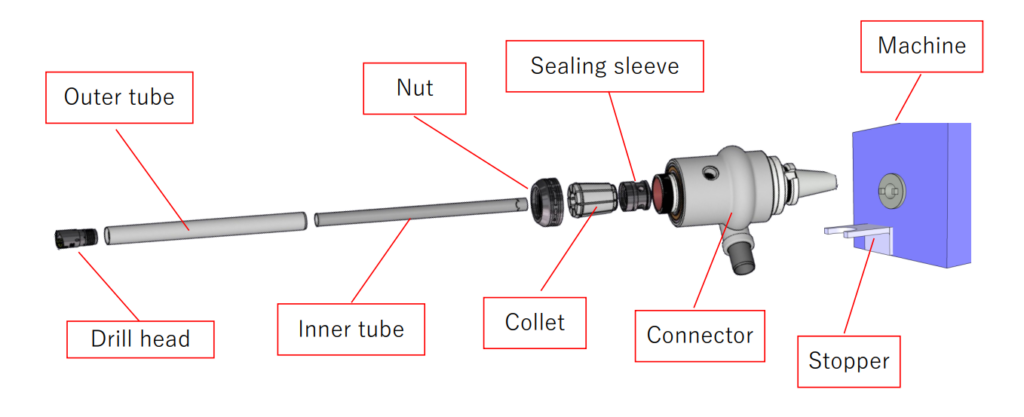

The original process consisted of 3 spade drills of different sizes.

Utilizing Double Tube System we could increase productivity and reduce machine down time.

Using Double tube system we can get rid of time costly tool change and drill to depth in one go.

As a final result we managed to reduce the cycle time 5 times.

Share

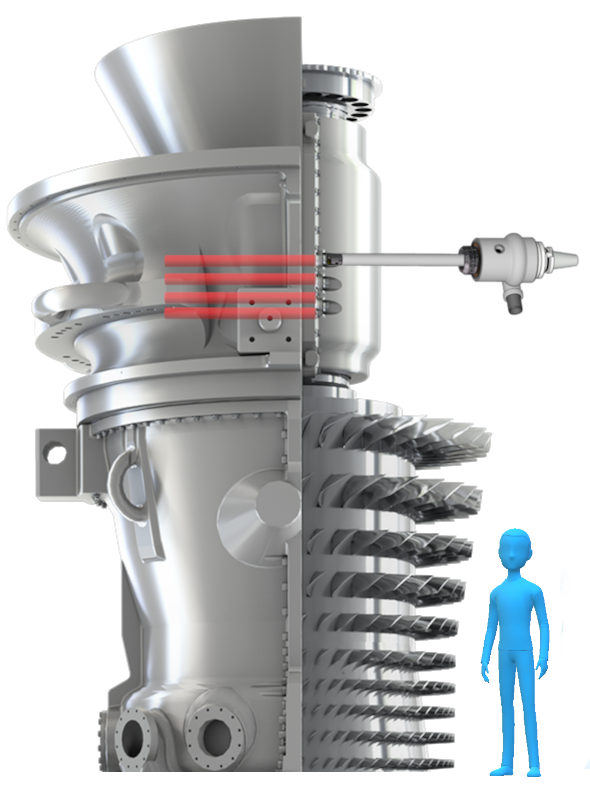

| Industry | Power Generation |

|---|---|

| Component | Turbine Housing |

| Material ISO code |

|

| Work material | SC450 |

| Machine(spindle type) | Horizontal Machining Center |

| Tool family | Holemaking |

| Tool category | Deep hole drilling |

| Product name | BTA |

| TSR No. | 5168D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | FNBM-08D-38.00 | Spade Drill |

| Insert | FBH080408R-HF-P AH9130 | |

| Grade | AH9130 | cemented carbide |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 38 | 38 |

| Hole depth H (mm) | 2080 | 2080 |

| Cutting speed V/c (m/min) | 64 | 25 |

| Feed f (mm/rev) | 0.11 | 0.3 |

| Feed speed Vf (mm/min) | 59 | 63 |