DeepTriDrill – Increased Productivity

IMPROVE PRODUCTIVITY

Positive result, achieving improved productivity.

table feed improved 30% against the rival brazed gundrill.

The drill exhibited excellent surface quality.

Customer was also able to eliminate grinding and coating process.

Share

| Industry | Engineering |

|---|---|

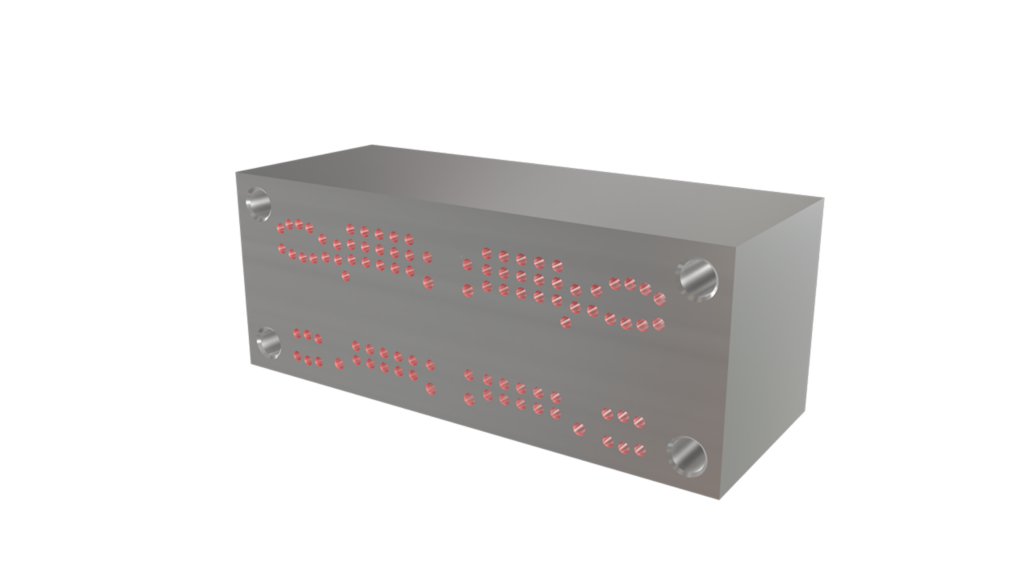

| Component | Blocks |

| Material ISO code |

|

| Work material | Aluminum Alloy |

| Machine(spindle type) | Horizontal Machining Center |

| Tool family | Holemaking |

| Tool category | Deep hole drilling |

| Product name | DeepTri-Drill |

| TSR No. | 5157D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | MCTR12.00XM20-20 | Brazed Gun-drill |

| Insert | LOGT 060204R-DT AH725 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 12.00 | 12.00 |

| Hole tolerance grade | 0.1 | 0.1 |

| Pilot hole diameter (mm) | 12.00 | 12.00 |

| Hole depth H (mm) | 250 | 250 |

| Cutting speed V/c (m/min) | 98 | 90 |

| Feed f (mm/rev) | 0.12 | 0.1 |

| Feed speed Vf (mm/min) | 312 | 239 |