MillQuadFeed15 – Power Generation Part – U type insert

IMPROVED PRODUCTIVITY

The workpiece is made of exotic stainless steel and has an extremely long machining length.

In an effort to improve productivity, the customer increased cutting parameters using the competitor’s tool, but short tool life prevented any productivity gains.

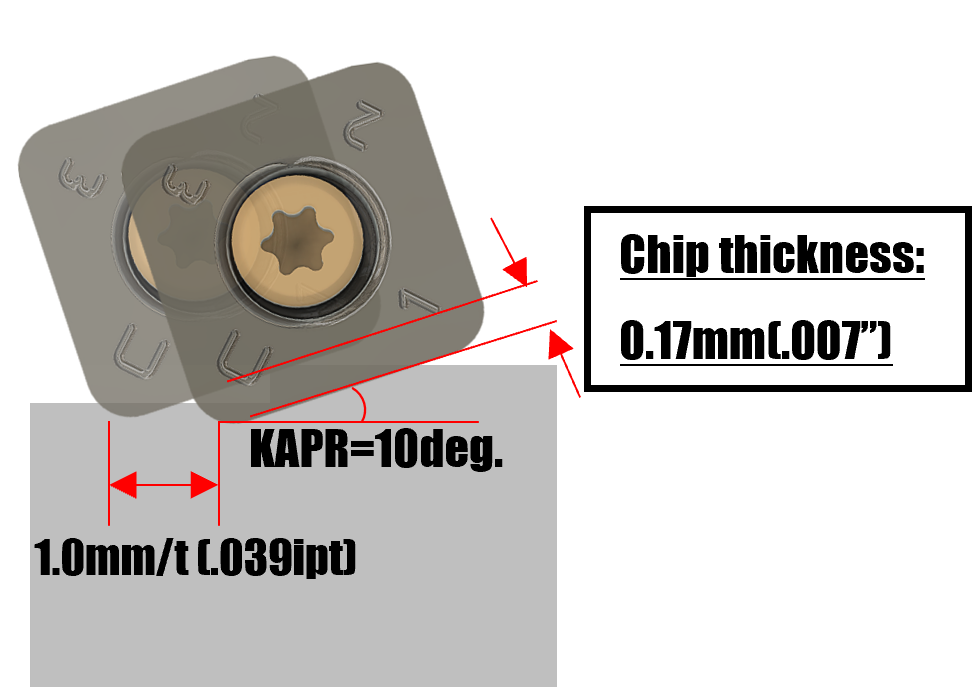

MillQuadFeed-U type inserts reduced cutting heat by generating thin chips through a low KAPR effect, effectively preventing edge fracture.

As a result, cutting parameters were optimized, leading to a 9 times increase in productivity.

Share

| Industry | Power Generation |

|---|---|

| Component | Power generation part |

| Material ISO code |

|

| Work material | SUS329J1 |

| Machine(spindle type) | Vertical Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | High feed milling |

| Product name | MillQuadFeed |

| TSR No. | 5125M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TXSW15J125B38.1R07 | High feed cutter |

| Number of teeth | 7 | 6 |

| Cutting diameter | 125(5") | 125(5") |

| Insert | SWMT1506UER-MM | Square, positive inserts |

| Number of cutting edges | 4 | 4 |

| Grade | AH3135 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 150 (492 sfm) | 80 (263 sfm) |

| Feed per tooth f/z (mm/t) | 1.0 (.039 ipt) | 0.5 (.020 ipt) |

| Feed speed Vf (mm/min) | 2,674 (105.28 ipm) | 611 (24.06 ipm) |

| Depth of cut ap (mm) | 1.0 (.039”) | 0.5 (.020”) |

| Width of cut ae (mm) | 70 (2.756”) | 70 (2.756”) |