MillQuadFeed09 – Shroud Ring – U type insert

IMPROVED TOOL LIFE & PRODUCTIVITY

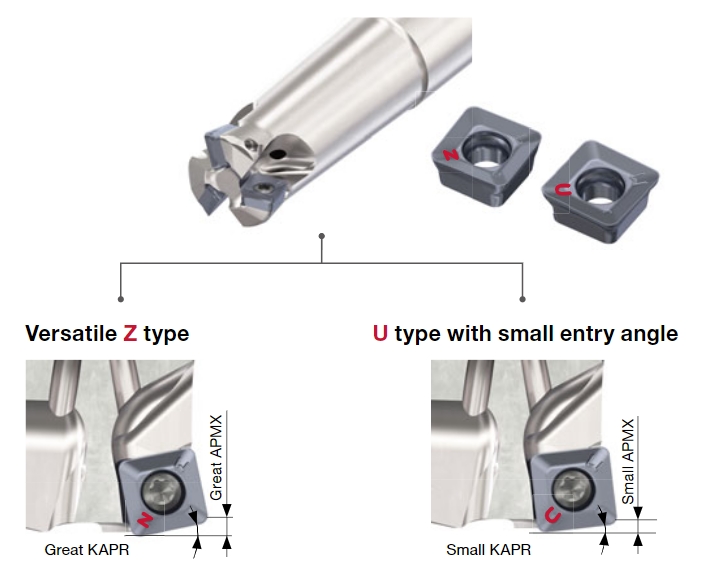

The challenge of short tool life in machining heat-resistant superalloys was addressed by implementing U-type geometry combined with the AH8015 grade.

This optimization of the small KAPR, along with the grade's thermal resistance, resulted in a 3.3 times increase in tool life.

In addition, productivity increased by 1.4 times due to the increased number of teeth.

Share

| Industry | Power Generation |

|---|---|

| Component | Gas Turbine Blade |

| Material ISO code |

|

| Work material | Hastelloy |

| Machine(spindle type) | Vertical Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | High feed milling |

| Product name | MillQuadFeed |

| TSR No. | 5123M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TXSW09M050B22.0R07 | High feed cutter |

| Number of teeth | 7 | 5 |

| Cutting diameter | 50 (1.97") | 50 (1.97") |

| Insert | SWMT0904UER-MM | Positive insert |

| Number of cutting edges | 4 | 4 |

| Grade | AH8015 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 100 (328sfm) | 100 (328sfm) |

| Feed per tooth f/z (mm/t) | 0.2 (.0787ipt) | 0.2 (.0787ipt) |

| Feed speed Vf (mm/min) | 890 (35.0ipm) | 640 (25.2ipm) |

| Depth of cut ap (mm) | 1.0 (.0393") | 1.0 (.0393") |

| Width of cut ae (mm) | 30.0 (1.18") | 30.0 (1.18") |

| Coolant | Wet | Wet |