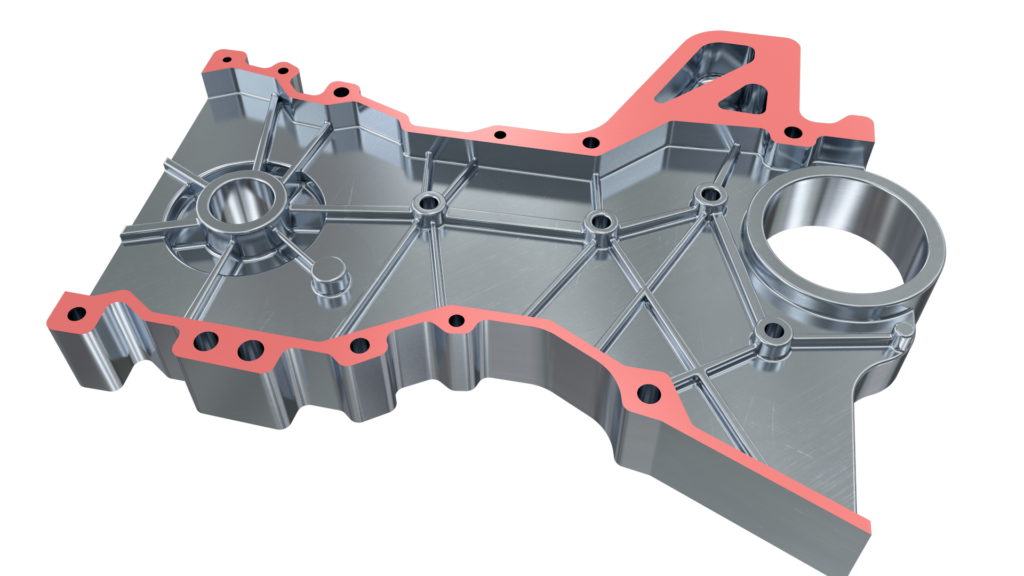

TungSpeedMill – Timing chain case – ADC12

IMPROVED PRODUCTIVITY

TungSpeedMill achieved 1.5 times higher efficiency in roughing and 2.0 times higher efficiency in finishing through its multi-tooth design.

The competitor's product started generating burrs at approximately 3,500 pieces, requiring manual until reaching its set tool life of 27,400 pieces.

TungSpeedMill, even after processing 20,000 pieces, did not produce burrs, eliminating the need for manual deburring, an outcome that was well received.

Share

| Industry | Automotive |

|---|---|

| Component | Timing chain case |

| Material ISO code |

|

| Work material | ADC12 |

| Machine(spindle type) | Vertical Machining Center Small(#30,HSK40) |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | TungSpeed-Mill (TPYD, EPYD) |

| TSR No. | 5066M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TPYD06M050B22.0R10 | PCD Face mill cutter |

| Number of teeth | 10 | 5 |

| Cutting diameter | 50 | 50 |

| Insert | YDEN0603PDFR-D | PCD insert |

| Number of cutting edges | 1 | 1 |

| Grade | DX110 | PCD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 1571(Roughing), 1256(Finishing) | 1571(Roughing), 1256(Finishing) |

| Feed per tooth f/z (mm/t) | 0.06(Roughing), 0.05(Finishing) | 0.08(Roughing), 0.05(Finishing) |

| Depth of cut ap (mm) | 0.5(Roughing), 0.5(Finishing) | 0.5(Roughing), 0.5(Finishing) |

| Width of cut ae (mm) | ~40 | ~40 |

| Coolant | Wet(Internal) | Wet(Internal) |