TungAluMill – Chamber – TH10

IMPROVED PRODUCTIVITY

Productivity

– Higher number of Pockets in the cutter body improves productivity in large material scooping by up to 1.3 times.

Tool stability

– Insert’s high positive rake face reduces cutting forces thus resisting vibrations even with higher number of pockets in the tool.

Share

| Industry | Aerospace |

|---|---|

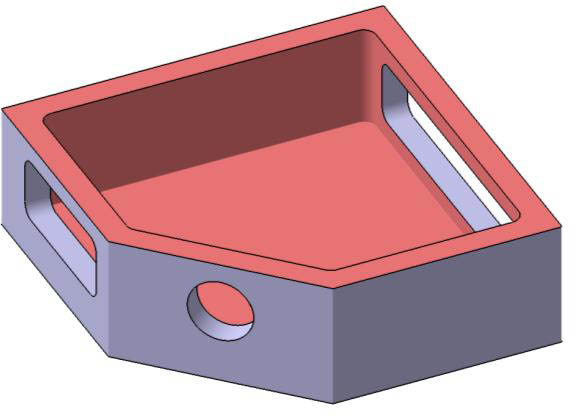

| Component | Chamber |

| Material ISO code |

|

| Work material | 6061 |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Milling |

| Tool category | Pocketing |

| Product name | TungAluMill |

| TSR No. | 329M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TPV16R200U0075A04 | Shoulder milling cutter |

| Effective number of teeth | 4 | 3 |

| Cutting diameter | 50.8 | 50.8 |

| Insert | XVCT160508R-AJ | 2 corner positive insert |

| Number of cutting edges | 2 | 2 |

| Grade | TH10 | Non coated carbide |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 1000 | 1000 |

| Feed per tooth f/z (mm/t) | 0.2 | 0.2 |

| Feed speed Vf (mm/min) | 5119 | 3839 |

| Depth of cut ap (mm) | 6.35 | 6.35 |

| Width of cut ae (mm) | 44.5 | 44.5 |

| Coolant | Wet (External) | Wet (External) |