AddDoFeed – Die – SKD11

IMPROVED PRODUCTIVITY AND TOOL LIFE

Previously, a competitor's high-feed cutter was used for pocket machining of HRC60 SKD11.

We proposed the AddDoFeed for this machining process.

Despite being a small-diameter cutter, the AddDoFeed demonstrated superior reliability and enabled a higher feed rate compared to the conventional product, improving productivity by 1.5 times.

Additionally, tool life was extended by 3.5 times. The AddDoFeed features four corners per insert compared to the conventional product's two corners, significantly reducing insert consumption through extended tool life and increased number of corner.

Share

| Industry | Die & Mold |

|---|---|

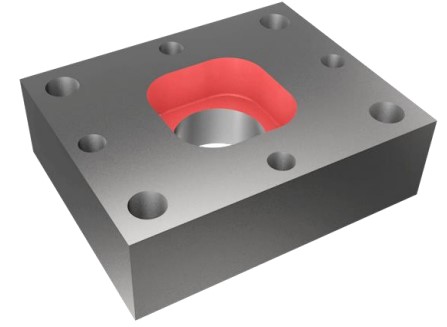

| Component | Mold |

| Material ISO code |

|

| Work material | SKD11 |

| Material hardness | 60HRC |

| Machine(spindle type) | Machining Center Small(#30,HSK40) |

| Tool family | Milling |

| Tool category | Pocketing |

| Product name | AddDoFeed |

| TSR No. | 5041M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | EXN02R010M10.0 -02L | High feed cutter |

| Effective number of teeth | 2 | 2 |

| Cutting diameter | 10 | 10 |

| Insert | LNMU0202ZER -MM | Positive insert |

| Number of cutting edges | 4 | 2 |

| Grade | AH8015 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 60 | 60 |

| Feed per tooth f/z (mm/t) | 0.3 | 0.2 |

| Feed speed Vf (mm/min) | 1150 | 765 |

| Depth of cut ap (mm) | 0.3 | 0.3 |

| Width of cut ae (mm) | ~10 | ~10 |

| Coolant | Wet | Wet |