DoFeed – Titanium Aero Parts – AH130

IMPROVED PRODUCTIVITY AND TOOL LIFE

High productivity

– DoFeed could machine Titanium with high feed speed because of incredibly close pitch design. Inaddition, ML chip breaker's low cutting force prevents chattering even in high feed speed.

Long tool life

– DoFeed machined 2.5 times higher number of the parts than competitor’s tool by the end of tool life by preventing chip welding and coating peel off.This is because sharper ML chipbreaker and grade AH130.

Share

| Industry | Aerospace |

|---|---|

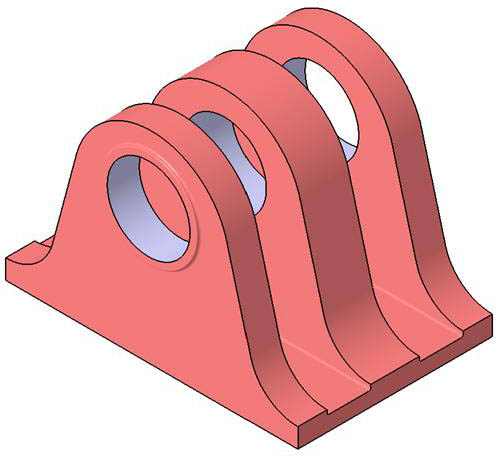

| Component | Titanium Aero Parts |

| Material ISO code |

|

| Work material | Ti-6Al-4V |

| Machine(spindle type) | Horizontal Machining Center |

| Tool family | Milling |

| Tool category | Pocketing |

| Product name | DoFeed |

| TSR No. | 335M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | EXN03R025M25.0-05 | High feed cutter |

| Effective number of teeth | 5 | 2 |

| Cutting diameter | 25 | 25 |

| Insert | LNMU0303ZER-ML | 4 corner positive insert |

| Number of cutting edges | 4 | 4 |

| Grade | AH130 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 40 | 37 |

| Feed per tooth f/z (mm/t) | 0.707 | 1.078 |

| Feed speed Vf (mm/min) | 1800 | 1016 |

| Depth of cut ap (mm) | 0.8 | 0.8 |

| Width of cut ae (mm) | Variable | Variable |

| Coolant | Wet (water soluble) | Wet (water soluble) |