DeepTriDrill – Subsea equipment – AH9130

Boost deep drilling operations with Deep TriDrill

Test on AISI 316 stainless steel revealed significant benefits.

Target is to improve productivity and reduce the overall cost of the drilling operation.

Result showed cutting time reduction from 835 seconds to just 161 seconds.

The new tool also delivered a cost reduction of 95.2% per part,

DeepTriDrill produced excellent surface quality and acceptable runout.

Innovative solution not only boosts productivity but also makes a significant impact on overall cost reduction.

Share

| Industry | Oil & Gas |

|---|---|

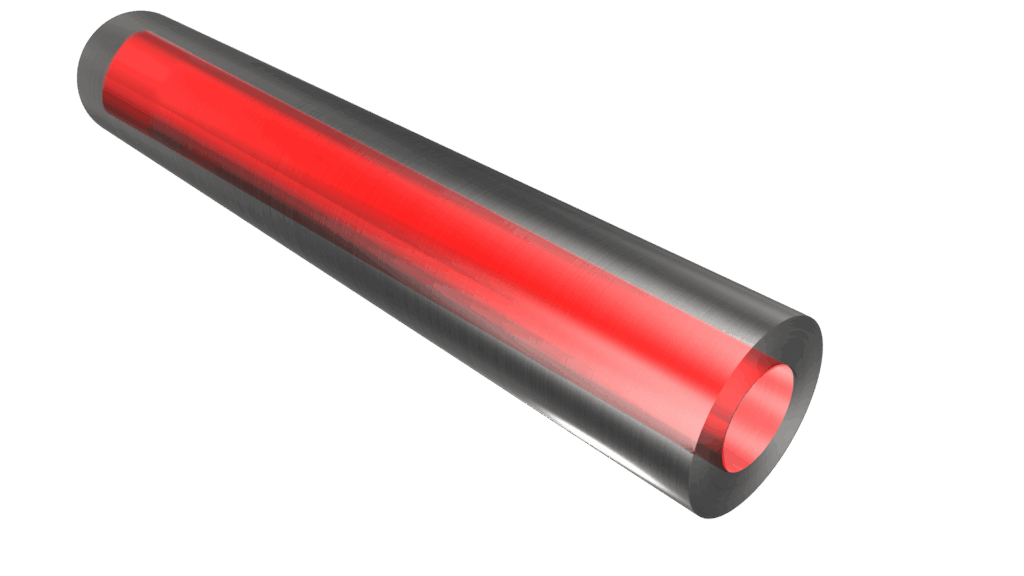

| Component | subsea equipment - Round bar stock |

| Material ISO code |

|

| Work material | AISI 316 |

| Machine(spindle type) | Dedicated Machine |

| Tool family | Holemaking |

| Tool category | Deep hole drilling |

| Product name | DeepTri-Drill |

| TSR No. | 5184D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TRLG09.53X1245-U05 | brzazed gundrill |

| Insert | ZSGT050104R-NDJ AH9130 | brazed tip |

| Grade | AH9130 | brazed tip |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 5 | 0.8 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 9.53 | 9.53 |

| Hole depth H (mm) | 432 | 432 |

| Feed f (mm/rev) | .079 | .025 |

| Feed speed Vf (mm/min) | 160 | 31 |