DrillMeister – Brake dick rotor – DMP special head

IMPROVE TOOL LIFE

Drilling process for bolt hole of Brake dick rotor. The existed drill generates burrs at the end of its tool life, which limits its overall usability.

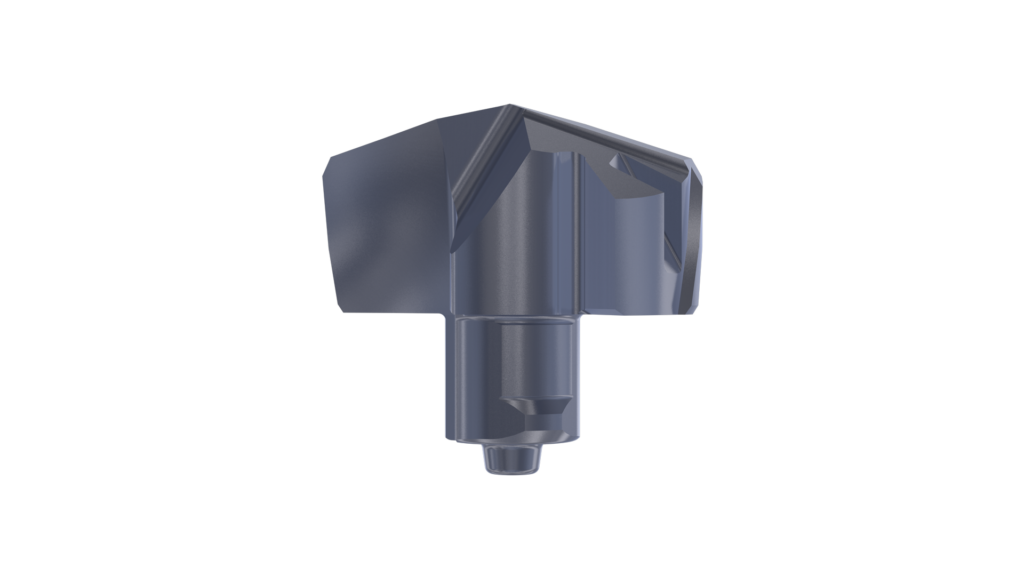

The specially designed DrillMeister DMP head, featuring a dedicated chamfer edge to minimize burr formation, has been adopted.

Improvements in wear resistance and burr control have successfully doubled the tool life.

Share

| Industry | Automotive |

|---|---|

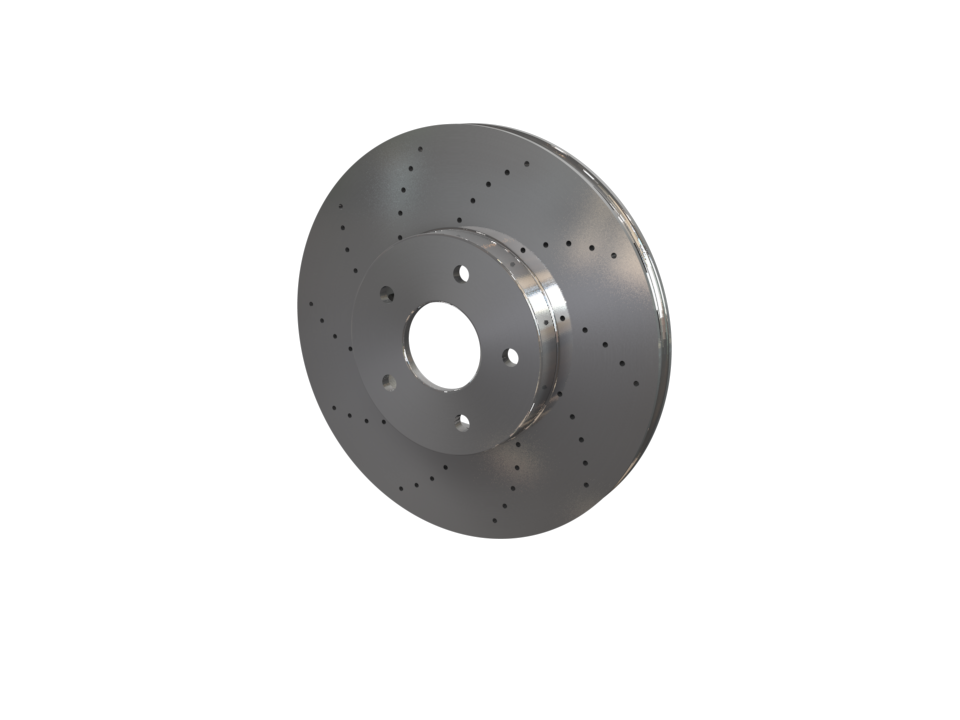

| Component | Brake Dike rotor |

| Material ISO code |

|

| Work material | FC250/GG25/No30B |

| Machine(spindle type) | Machining Center Middle(#40,HSK63) |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillMeister |

| TSR No. | 5186D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TID165F20-3 | Head exchangable drill 3xD |

| Head | DMP165-with chamfer AH725 | Drill head |

| Grade | AH725 | PVD P20 |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 60 | 30 |

| Number of workpieces (pcs/insert) | 2000 | 1000 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 16.5 | 16.5 |

| Hole tolerance grade | IT10 | IT10 |

| Hole depth H (mm) | 6 | 6 |

| Cutting speed V/c (m/min) | 100 | 100 |

| Feed f (mm/rev) | 0.25 | 0.25 |

| Feed speed Vf (mm/min) | 482 | 482 |

| Coolant | Non | Non |