IMPROVED TOOL COST AND IMPROVED PROCESS RELIABILITY

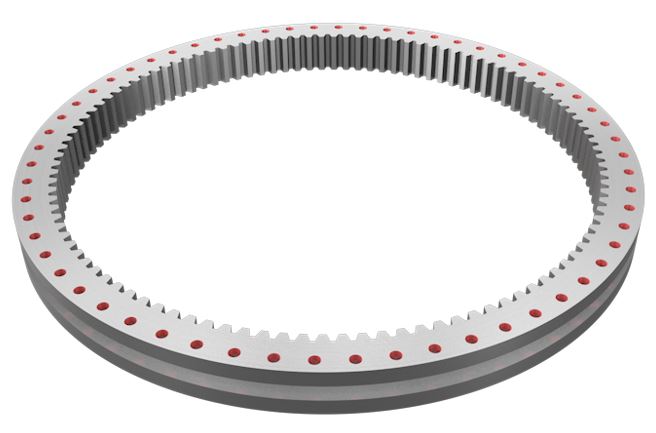

Hole machining of cast iron inner gears for construction machinery.

Previously, we used a competitor's indexable drill, but due to the hardness of the workpiece, frequent chipping of the central cutting edge insert occurred after processing 20 holes per edge.

In response to this, we proposed the combination of the TungSix-Drill and the new grade AH7030.

The synergy between the high central edge strength of the TungSix-Drill and the reliable AH7030 grade suppressed the chipping of the central cutting edge insert.

Additionally, compared to the conventional four-corner insert, the TungSix-Drill uses a six-corner insert, reducing the amount of insert usage.

As a result, both tool costs were reduced, and machining reliability was improved.