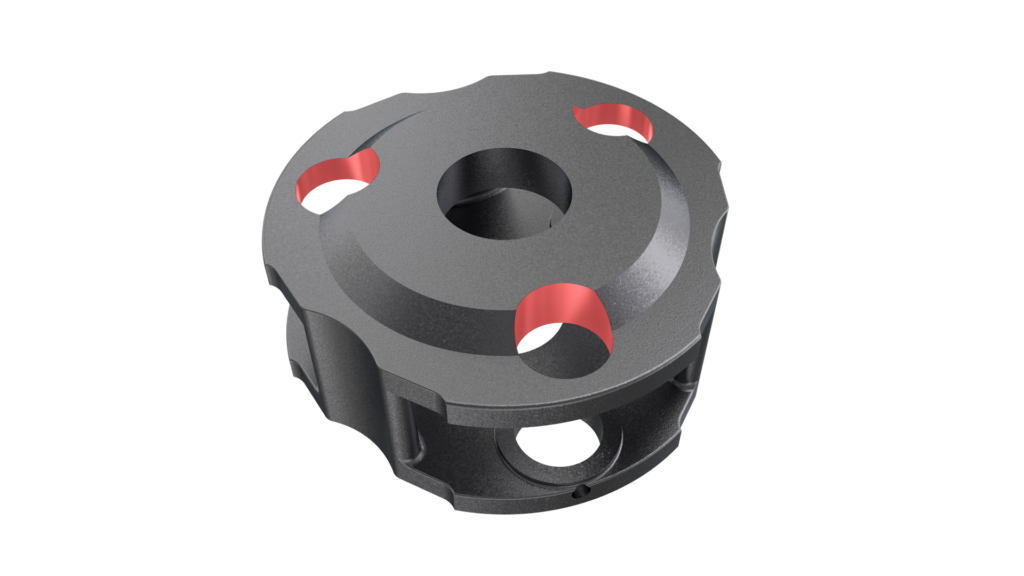

ReamMeister – Carrier – AH725

IMPROVED TOOL LIFE & PRODUCTIVITY

The conventional solid reamer with straight flutes frequently experienced short stoppages due to chip entanglement.

The BL blade design of the ReamMeister successfully improved operational efficiency by ejecting chips forward, preventing them from getting tangled around the tool body. Additionally, internal coolant supply enhanced cutting speed while significantly extending tool life.

Share

| Industry | Heavy |

|---|---|

| Component | Carrier |

| Material ISO code |

|

| Work material | C50 |

| Machine(spindle type) | Duplex Milling Machine |

| Tool family | Holemaking |

| Tool category | Reaming |

| Product name | ReamMeister |

| TSR No. | 5168D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TRM-T7-R20-5 | Solid carbide |

| Head | HRM-18.000-BL-T7 | - |

| Grade | AH725 | Non coated carbide |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Number of workpieces (pcs/insert) | 17 | 2 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 18 | 18 |

| Hole tolerance grade | H7 | H7 |

| Pilot hole diameter (mm) | 17.8 | 17.8 |

| Hole depth H (mm) | 80 | 80 |

| Cutting speed V/c (m/min) | 80 | 50 |

| Feed f (mm/rev) | 0.3 | 0.3 |

| Feed speed Vf (mm/min) | 424 | 265 |

| Coolant | Internal | External |