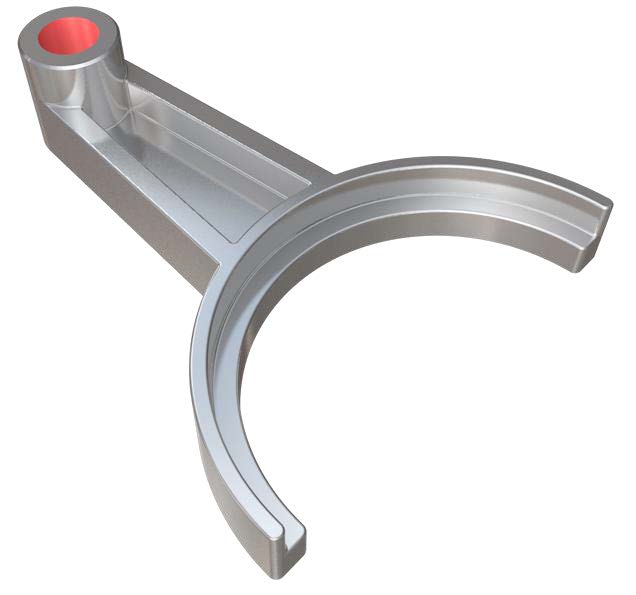

ReamMeister – Shift Fork – AH725

IMPROVED PRODUCTIVITY & TOOL COST

ReamMeister exchangeable head system cost 1/3 of conventional solid reamer. RM still remains cost efficient even without regrinding service. In addition, the customer was using the solid reamer at low cutting parameters to avoid edge fracture that could not be repaired by regrinding. Hence, 1.8 times productivity increase was achieved with RM combined with consistent part precision.

Share

| Industry | Automotive |

|---|---|

| Component | Shift Fork |

| Material ISO code |

|

| Work material | FCD600 |

| Machine(spindle type) | Horizontal Machining Center Large(#50,HSK100) |

| Tool family | Holemaking |

| Tool category | Reaming |

| Product name | ReamMeister |

| TSR No. | 1648D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TRM-T8-R20-3 | Solid carbide reamer |

| Head | HRM-23.000-BL-T8 | φ23, z=8 |

| Grade | AH725 | PVD, K10 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 23 | 23 |

| Hole tolerance grade | H8 | H8 |

| Pilot hole diameter (mm) | 22.8 | 22.8 |

| Hole depth H (mm) | 40 | 40 |

| Cutting speed V/c (mm/min) | 100 | 90 |

| Feed f (mm/rev) | 0.8 | 0.5 |

| Feed speed Vf (mm/min) | 1100 | 620 |

| Coolant | Internal | Internal |