IMPROVED PRODUCITIVTY

Reducing drilling costs and increase productivity.

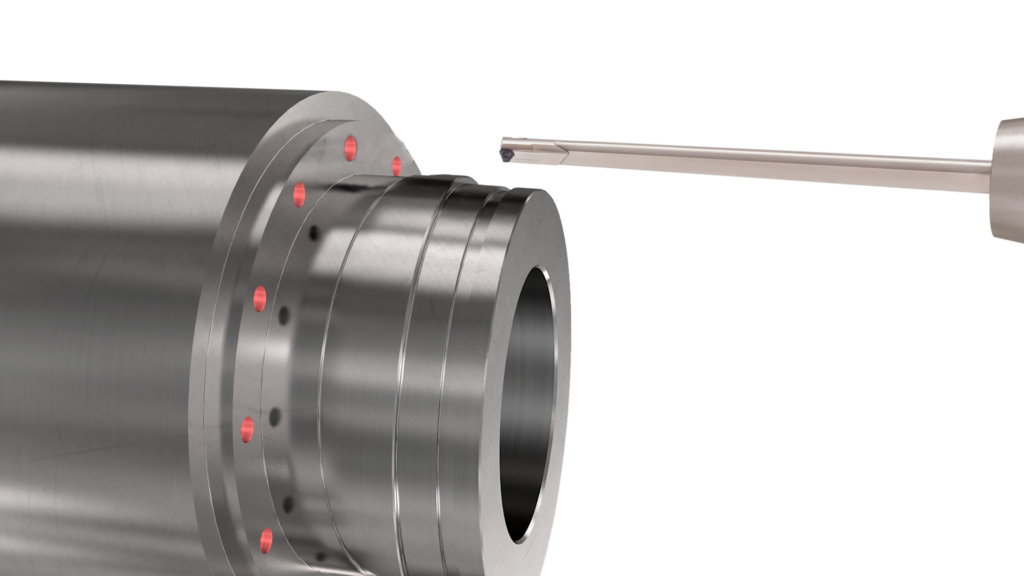

Our approach to drilling in Inconel 718 allows the end user to consolidate operations previously split between two machines into a single machine setup. This is achieved by performing the entire drilling process in one chuck setup.

Operation is divided into three strategic steps: short hole, medium hole, and final long hole. By optimizing the setup and increasing coolant concentration to 17%, the need for frequent tool adjustments is minimized. hole deflection is kept to a minimal 0.1mm/meter.

This streamlined process resulted in:

1- cycle time reduced from 7.5 hours to just 2.3 hours

2- machine downtime reduced from 225min. to 75min.

3- tool life extended by 3 times.

This method also opens the door to other turning and milling application on a multitasking machine.