DrillMeister – Producitivity improvement – Special solution Front and Back chamfer

IMPROVE MACHINING TIME

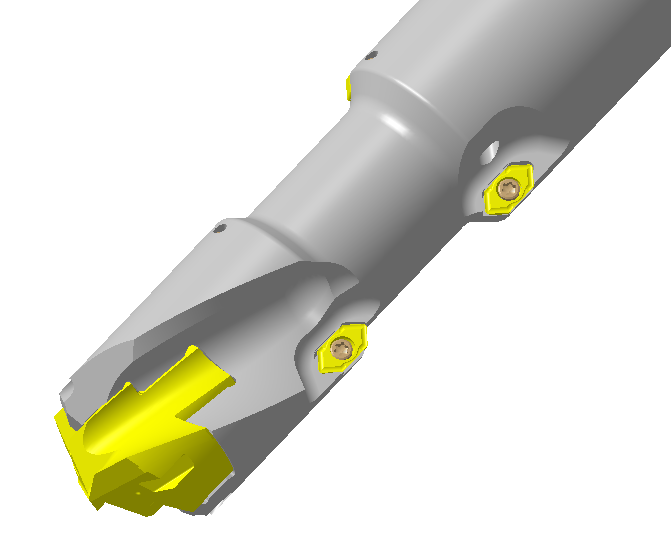

The workpiece needed to be drilled and chamfered on both the front and back sides. Traditionally, after drilling, a separate tool was required for front chamfering, and the workpiece had to be flipped over for back chamfering, taking 90 seconds per hole. With DrillMeister's innovative solution, both drilling and chamfering can be completed with a single tool, eliminating the need to flip the workpiece and reducing the total process time to just 15 seconds.

Share

| Industry | Heavy |

|---|---|

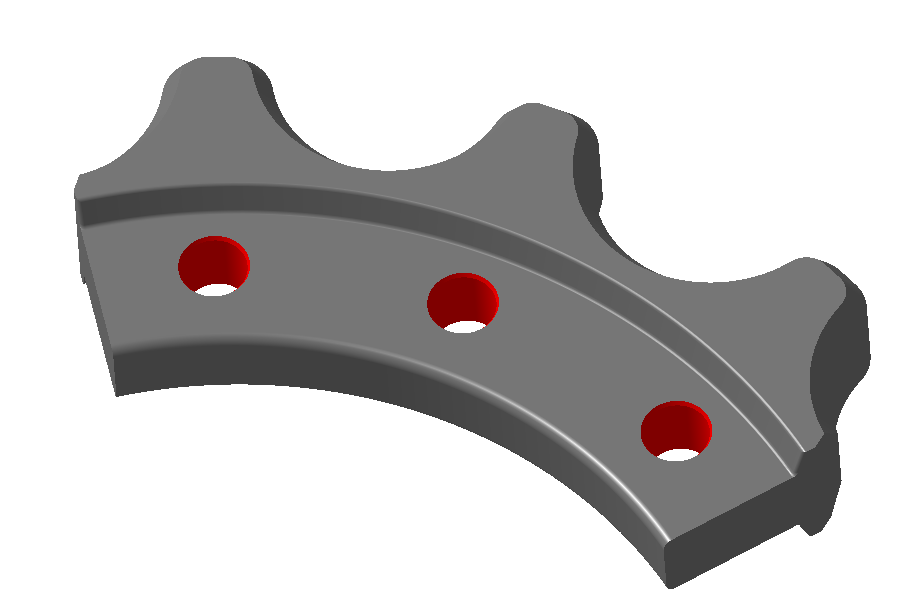

| Component | Sprocket |

| Material ISO code |

|

| Work material | 34CrMo4 |

| Machine(spindle type) | Vertical Machining Center Large(#50,HSK100) |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillMeister special body |

| TSR No. | 5151H |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TID235L33C0.5BC0.5L150R32 | Head exchangable drill and chamfer tool |

| Head | DMP235 AH9130 | |

| Grade | AH9130 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 23.5 | 23.5 |

| Hole tolerance grade | IT10 | IT10 |

| Hole depth H (mm) | 20 | 20 |

| Cutting speed V/c (m/min) | 80 | 80 |

| Feed f (mm/rev) | 0.3 | 0.20 |

| Feed speed Vf (mm/min) | 325 | 282 |

| Coolant | Internal coolant | Internal coolant |