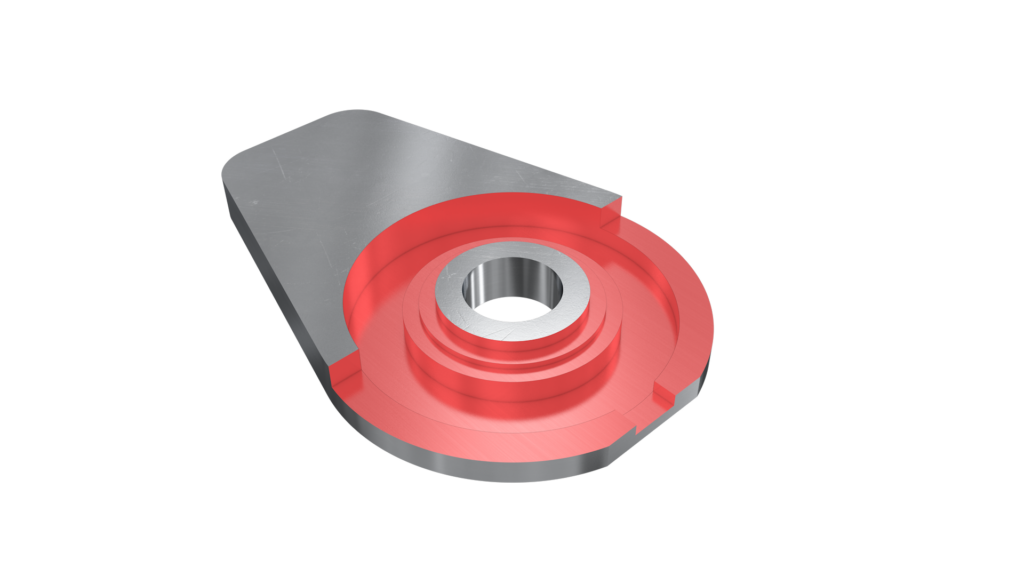

TungAlumill – Semiconductor manufacturing part – TH10

IMPROVED PRODUCTIVITY AND TOOL LIFE

The unique insert geometry, specifically designed for efficient machining of aluminum, achieves higher productivity and longer tool life.

Share

| Industry | Engineering |

|---|---|

| Component | Semiconductor Production Equipment |

| Material ISO code |

|

| Work material | ADC12 |

| Machine(spindle type) | Vertical Machining Center Middle(#40,HSK63) |

| Tool family | Milling |

| Tool category | Pocketing |

| Product name | TungAluMill |

| TSR No. | 5075M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TPXV16M050B22.0R04 | Square shoulder mill |

| Number of teeth | 4 | 5 |

| Cutting diameter | 50 | 50 |

| Overhang (mm) | 100 | 100 |

| Insert | XVCT160504PEFR-AM | Positive inserts |

| Number of cutting edges | 2 | 2 |

| Grade | TH10 | Uncoated carbide |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 800 | 800 |

| Feed per tooth f/z (mm/t) | 0.2 | 0.15 |

| Feed speed Vf (mm/min) | 4,074 | 3,820 |

| Depth of cut ap (mm) | 3 | 3 |

| Width of cut ae (mm) | 20 | 20 |

| Coolant | WET | WET |