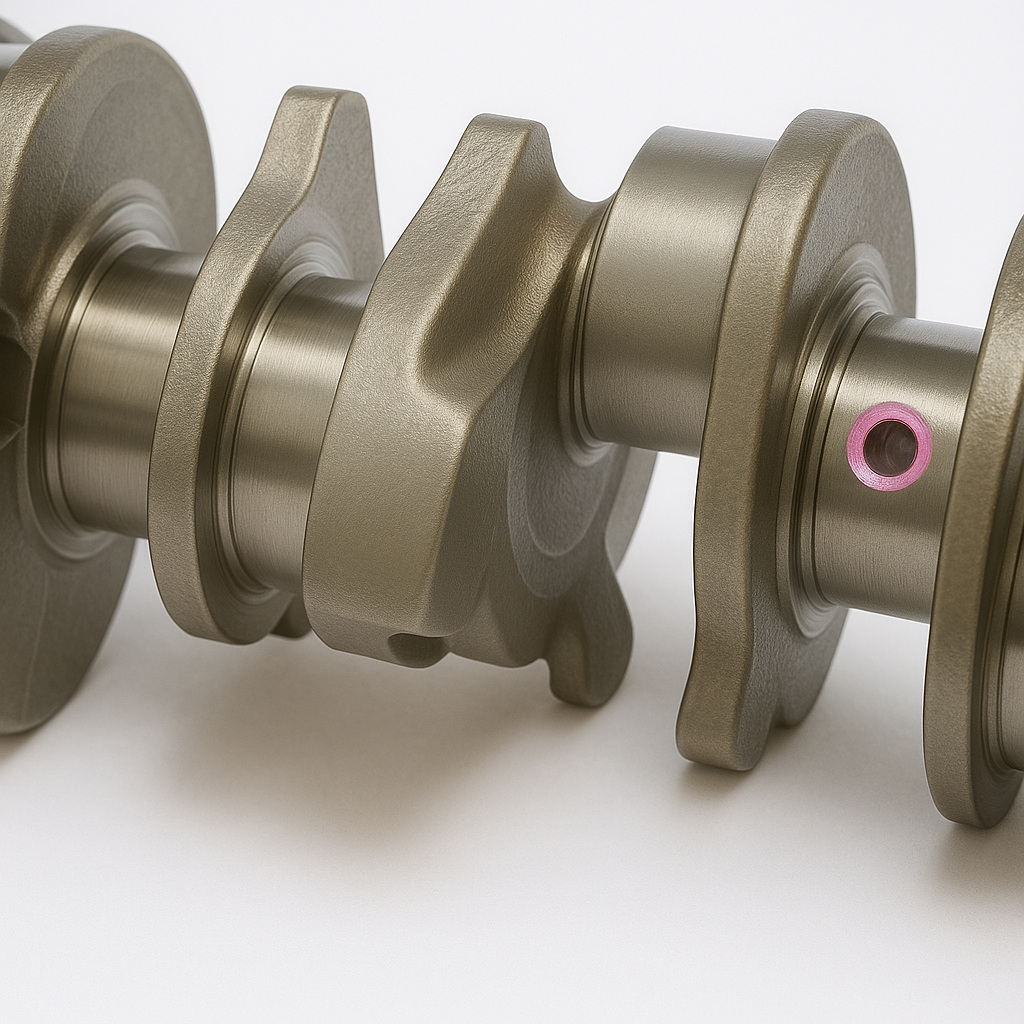

BallFinishNose – Crank Shaft – AH715

IMPROVED PRODUCTIVITY AND TOOL LIFE

The conventional product used a solid ball end mill for chamfering the holes in the crankshaft.

Due to the large chamfer width of 1.2 mm, chatter easily occurred in this process. For this process, we proposed a two-flute insert-type ball end mill.

The reduction in the number of flutes from four in the conventional product to two helped suppress the occurrence of chatter. Additionally, the switch to an insert-type tool reduced the unit price of the tool, cutting tool costs in half.

Share

| Industry | Automotive |

|---|---|

| Component | Crank Shaft |

| Material ISO code |

|

| Work material | S45C/C45 |

| Machine(spindle type) | Vertical Machining Center Small(#30,HSK40) |

| Tool family | Milling |

| Tool category | Chamfering |

| Product name | BallFinishNose |

| TSR No. | 5034M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | EBFM12S12S110 | Solid ball endmill |

| Effective number of teeth | 2 | 4 |

| Cutting diameter | 12 | 12 |

| Insert | ZFBM120R00MJ | |

| Number of cutting edges | 1 | 1 |

| Grade | AH710 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 40 | 27 |

| Feed per tooth f/z (mm/t) | 0.04 | 0.026 |

| Feed speed Vf (mm/min) | 85 | 75 |

| Depth of cut ap (mm) | 1.5 | 1.5 |

| Coolant | Dry | Dry |