SW and FW – Oil Seal – T9215

IMPROVED TOOL LIFE

Improved surface roughness and long tool life

- The competitor’s wiper insert was unable to provide the required surface roughness, Rz ≦ 4.5μm ,after cutting 200 pcs. FW chipbreaker delivered excellent surface quality even after machining 300pcs and also extended tool life by 1.5 times due to good wear resistance.

Stable machining

- FW chipbreaker with newly developed “two-stage protrusion” design provided better chip control than the competitor, resulting in stable machining.

Share

| Industry | Automotive |

|---|---|

| Component | Oil Seal |

| Material ISO code |

|

| Work material | SAPH440 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | SW and FW |

| TSR No. | 551T |

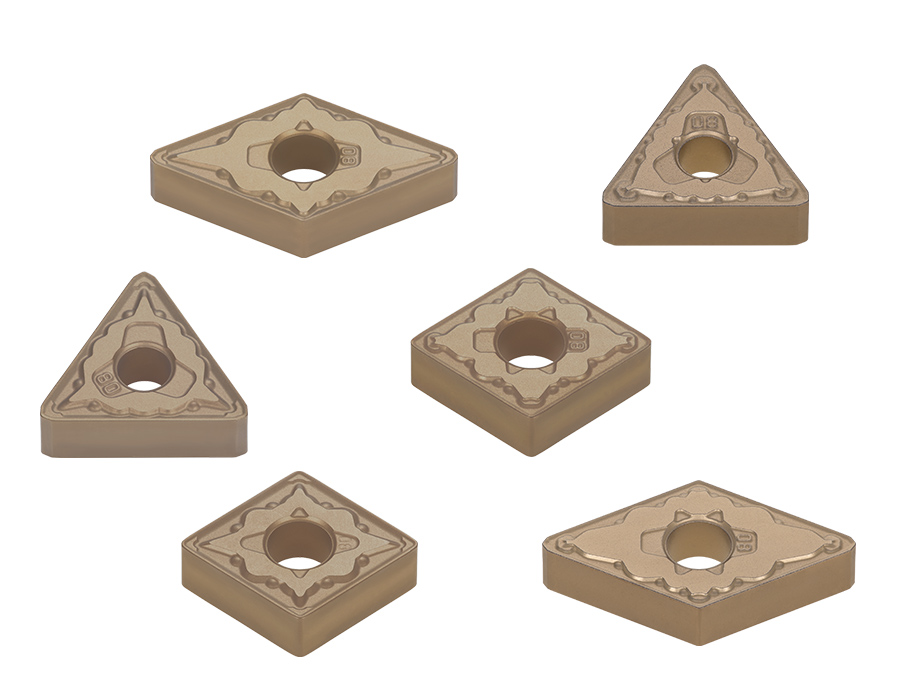

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | ACLNK2525M12-A | ACLNK2525M12-A |

| Insert | CNMG120408-FW | CNMG120408-With wiper |

| Grade | T9215 | CVD(P15) |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 300 | 200 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 250 | 250 |

| Feed f (mm/rev) | 0.3 | 0.3 |

| Depth of cut ap (mm) | 0.5 | 0.5 |

| Coolant | wet | wet |