AddMultiTurn – EV Shaft – T9215

IMPROVED TOOL LIFE

By applying back turning method with AddMultiTurn the customer gained 1.6 times higher productivity. Since a longer cutting edge is in contact with workpiece during back turning application, the cutting temperature was kept from rising by efficiently dispersing cutting heat. As the result, 1.7 times longer tool life was achieved.

Share

| Industry | Automotive |

|---|---|

| Component | Hollow shaft |

| Material ISO code |

|

| Work material | 16MnCrS5 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | AddMultiTurn |

| TSR No. | 1633T |

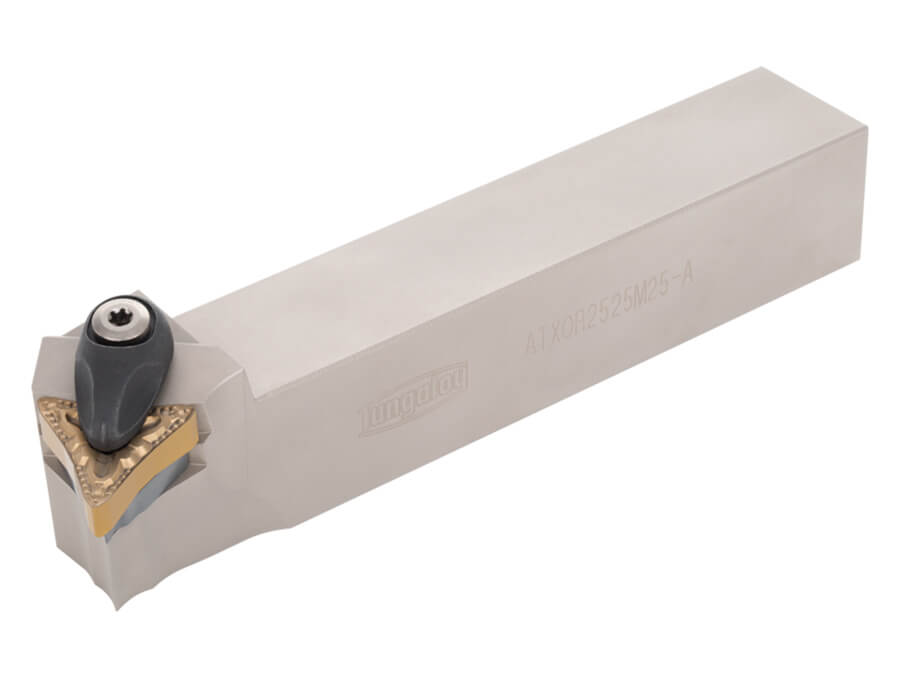

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | ATXOR2525M25-A | 25mm Square shank |

| Insert | 6C-TOMG250608M-TM | DNMG150612 With medium cutting geometry |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 180 | 180 |

| Feed f (mm/rev) | 0.8 | 0.5 |

| Depth of cut ap (mm) | 1.2 | 1.2 |

| Coolant | Wet | Wet |