AH8000 – Tube Parts – AH8015

Stable machining

- AH8015 features nano-multi-layered AlTiN coating with high Al content, the world’s first technology, which helps increase tool life due to excellent wear and chipping resistance in turning heat-resistant alloys.

Long tool life

- Unlike the competitor, AH8015 provides excellent wear and chipping resistance even in machining at high speeds over 100m/min, and the tool life is extended by 4 times.

Share

| Industry | Aerospace |

|---|---|

| Component | Tube Parts |

| Material ISO code |

|

| Work material | Hastelloy 276 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | AH8000 |

| TSR No. | 467T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | ACLNR2525M12-A | ACLNR2525M12-A |

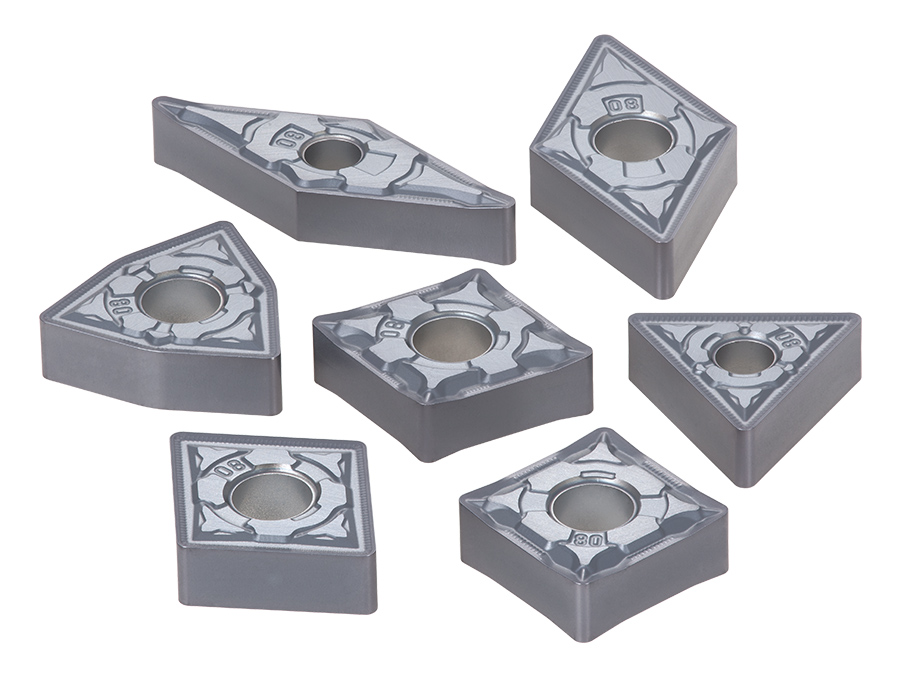

| Insert | CNMG120408-HRF | CNMG120408N-Finish chip breaker |

| Grade | AH8015 | CVD(M30) |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 4 | 1 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 140 | 140 |

| Feed f (mm/rev) | 0.1 | 0.1 |

| Depth of cut ap (mm) | 1.5 | 1.5 |

| Coolant | Wet | Wet |