TungMeister – Transmission Part – AH725

IMPROVEMENT OF TOOL LIFE AND PRODUCTIVITY

- Tool set-up time reduced drastically.

- Stable tool life by elimination of regrinding processes and use of new heads.

- No need to worry about tasks involved in regrinding.

Share

| Industry | Automotive |

|---|---|

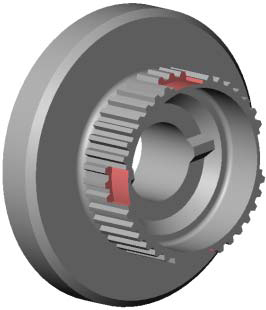

| Component | Transmission Parts |

| Material ISO code |

|

| Work material | 34Cr4 |

| Machine(spindle type) | Vertical Machining Center Small(#30,HSK40) |

| Tool family | Milling |

| Tool category | Shoulder milling |

| Product name | TungMeister |

| TSR No. | 021M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | VTSD12L080S05-S | Solid EndMill |

| Effective number of teeth | 3 | 3 |

| Cutting diameter | 8 | 8 |

| Insert | VEE080L05.0R00-03 | |

| Grade | AH725 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 80 | 80 |

| Feed per tooth f/z (mm/t) | 0.2 | 0.2 |

| Feed speed Vf (mm/min) | 3180 | 3180 |

| Depth of cut ap (mm) | 2.5 | 2.5 |

| Width of cut ae (mm) | 1 | 1 |

| Coolant | Wet | Wet |