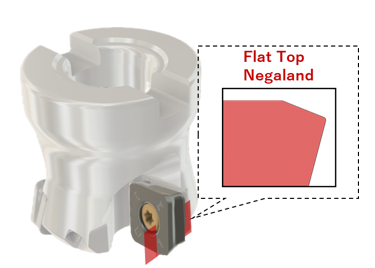

MillQuadFeed15 – Inconel cladding machining – Flat Top Inserts

IMPROVE TOOLLIFE & PRODUCTIVITY

The competitor’s tool suffered from rapid wear and long cycle times when machining Inconel 625 cladding. To overcome this, MillQuadFeed Flat-Top inserts were proposed. With excellent edge strength, they suppressed chipping even on welded surfaces with variable depths of cut, enabling stable high-feed machining. As a result, cycle time was reduced by 30% and tool life was extended by 30% compared to the competitor’s tool, achieving both higher productivity and longer tool life.

Share

| Industry | Oil & Gas |

|---|---|

| Component | Blocks |

| Material ISO code |

|

| Work material | Inconel Cladding 625 |

| Machine(spindle type) | Horizontal Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | High feed milling |

| Product name | MillQuadFeed |

| TSR No. | 5390M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TXSW15M050B22.0R03 | Face milling cuttre |

| Number of teeth | 3 | 5 |

| Cutting diameter | 50 | 63 |

| Insert | SWMW1506USR | Posi 8 corner |

| Number of cutting edges | 4 | 8 |

| Grade | AH8015 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 30 (98.4 sfm) | 23 (75.44 sfm) |

| Feed per tooth f/z (mm/t) | 0.2 (.0079 ipt) | 0.5 (.0197 ipt) |

| Feed speed Vf (mm/min) | 500 (19.69 ipm) | 200 (7.87 ipm) |

| Depth of cut ap (mm) | 1.0 (.039") | 1.0 (.039") |

| Coolant | External coolant | External coolant |