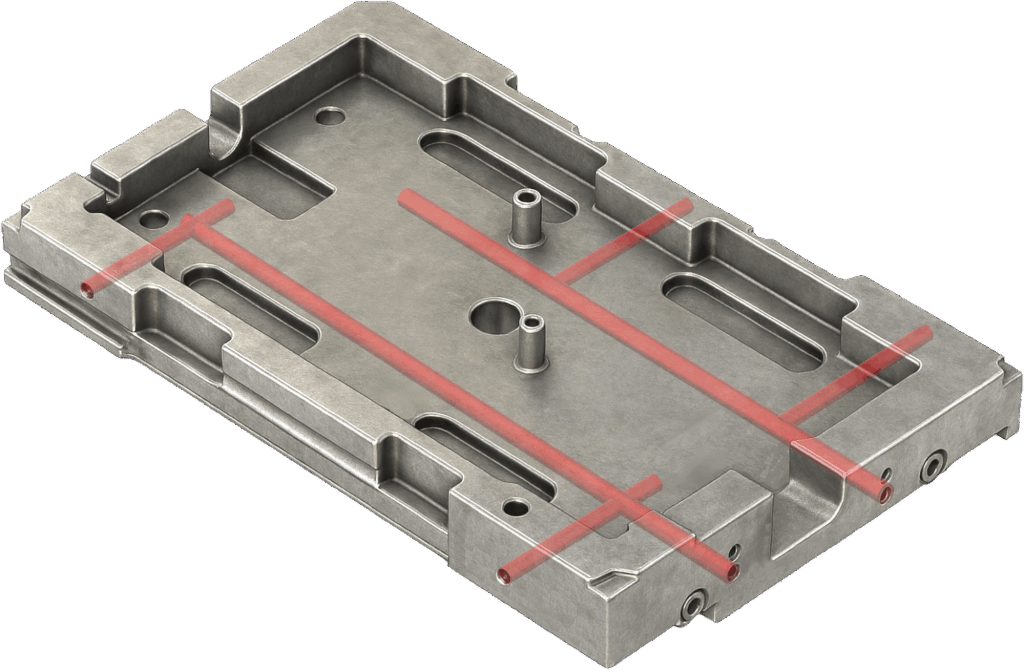

DeepTriDrill ‐ AHM930 – Distribution Plate

DeepTriDrill significant cost savings and enhanced performance with superb surface finish

DeepTridrill delivered exceptional performance drilling coolant channels on a Distribution Plate. Gun-drill machine with 35 KW power and 40 BAR pressure, our tool achieved excellent surface quality and a metal removal rate of 7.2 cm³/min.

Compared to the competitor, we reduced cutting time per hole from 23min to below 5 min, significantly lowering machining time and cost.

The tool maintained stable performance under interrupted cutting conditions and showed superior wear resistance. we achieved 12 holes per cutting edge versus 8 of the competitor.

Tool life, feed rates, and surface finish all improved, resulting in lower tooling costs and reduced downtime. The carbide-coated insert (AH9130) delivered consistent results on forged workpieces made of 1.2085 material.

Share

| Industry | Engineering |

|---|---|

| Component | Distribution Plate |

| Material ISO code |

|

| Work material | 1.2085 |

| Machine(spindle type) | Gun drill machine |

| Tool family | Holemaking |

| Tool category | Deep hole drilling |

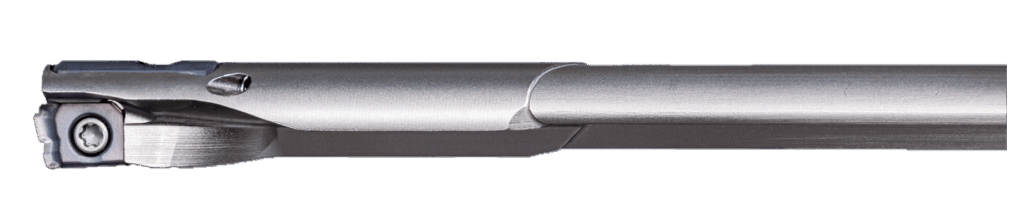

| Product name | DeepTri-Drill |

| TSR No. | 5187D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | MCTRCH08.00XM20-45 | Brazed Gun-Drill |

| Insert | ZSGT040104R-NDJ AH9130 | brazed tip |

| Grade | AH9130 | brazed tip |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Number of workpieces (pcs/insert) | 12 | 8 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 8 | 8 |

| Hole tolerance grade | 0.05 | 0.05 |

| Pilot hole diameter (mm) | 8 | 8 |

| Surface quality required Ra (μm) | Excellent | Good |

| Hole depth H (mm) | 640 | 640 |

| Cutting speed V/c (m/min) | 60 | 70 |

| Feed f (mm/rev) | 0.06 | 0.01 |

| Feed speed Vf (mm/min) | 143 | 28 |

| Coolant | Internal | Internal |