FinishMeister- Machine base- AH725

IMPROVED PRODUCTIVITY

Previously, roughing and finishing were performed using two separate end mills, but with the FinishMeister, both processes can be consolidated into a single tool.

In addition, because the FinishMeister is highly resistant to chatter, high-speed machining is now possible.

As a result of these advantages, the cycle time has been reduced by 60% compared to the conventional process.

Share

| Industry | Machine production |

|---|---|

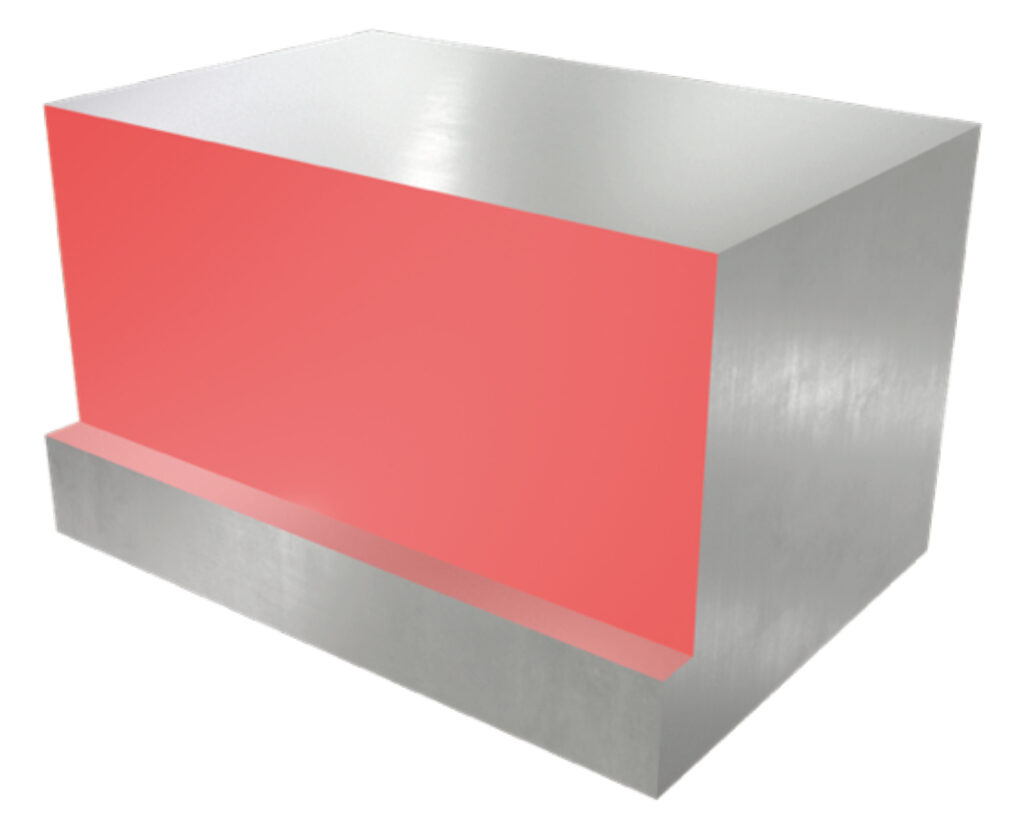

| Component | Base plate |

| Material ISO code |

|

| Work material | ASTM A36 |

| Machine(spindle type) | Horizontal Machining Center Middle(#40,HSK63) |

| Tool family | Milling |

| Tool category | Shoulder milling |

| Product name | FinishMeister |

| TSR No. | 5386M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TEFS120E44- 26C12CF83AH725 | 2 tools (Roughing and Square) |

| Number of teeth | 4 | 4/4 |

| Cutting diameter | 12 | 12/12 |

| Grade | AH725 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 200 | 120/120 |

| Feed per tooth f/z (mm/t) | 0.03 | 0.06/0.03 |

| Feed speed Vf (mm/min) | 637 | 764/382 |

| Depth of cut ap (mm) | 26 | 26/26 |

| Width of cut ae (mm) | 2 | 1.5/0.5 |

| Coolant | Extarnal | Extarnal |