TungRec – Machine Part – AH3225

IMPROVED PRODUCTIVITY & TOOL LIFE

TungRec with variable pitch design eliminated chatter, increasing MRR by 1.24 times. New wear-resistant grade AH3225 also helped prolong tool life by 1.15 times.

Share

| Industry | Engineering |

|---|---|

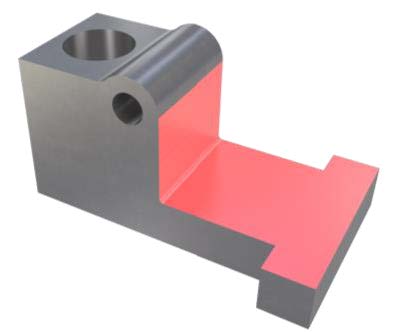

| Component | Machine Parts |

| Material ISO code |

|

| Work material | S17C |

| Machine(spindle type) | Horizontal Machining Center Middle(#40,HSK63) |

| Tool family | Milling |

| Tool category | Shoulder milling |

| Product name | TungRec |

| TSR No. | 1539M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | EPS11125RSBU | Square shoulder mill,Endmill type |

| Effective number of teeth | 5 | 5 |

| Cutting diameter | 31.75 | 31.75 |

| Overhang (mm) | 178 | 178 |

| Insert | ASMT11T330PDPR-MJ | Rectangular positive inserts |

| Number of cutting edges | 2 | 2 |

| Grade | AH3225 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (mm/min) | 190 | 270 |

| Feed per tooth f/z (mm/t) | 0.11 | 0.06 |

| Feed speed Vf (mm/min) | 1061 | 857 |

| Depth of cut ap (mm) | 3.65 | 3.65 |

| Width of cut ae (mm) | 27.3 | 27.3 |

| Coolant | External | External |