RoughingMill TungRec – Guide Rail for Forklift – T3225

IMPROVED PRODUCTIVITY

High productivity

-TungRec’s tougher substrate and geometry allowed increasing feed rate by 20%.

High stability

-TungRec Roughing endmill’s optimized flute design avoids vibration and achieves accurate width of slot.

Share

| Industry | Heavy |

|---|---|

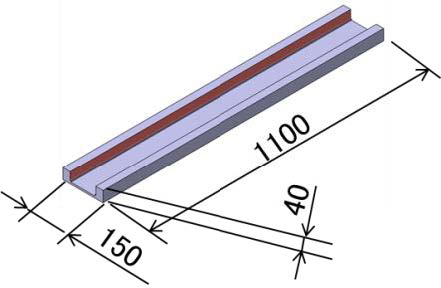

| Component | Guide Rail for Forklift |

| Material ISO code |

|

| Work material | SS400 |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Milling |

| Tool category | Shoulder milling |

| Product name | TungRec |

| TSR No. | 274M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TLS11R050M22.0E04 | Insert type Roughing EndMill |

| Effective number of teeth | 4 | 4 |

| Cutting diameter | 50 | 50 |

| Insert | ASMT11T308PDPR-MJ | 2 corner positive insert |

| Number of cutting edges | 2 | 2 |

| Grade | T3225 | 1025 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 220 | 220 |

| Feed per tooth f/z (mm/t) | 0.21 | 0.18 |

| Feed speed Vf (mm/min) | 1176 | 1008 |

| Depth of cut ap (mm) | 28.5 | 28.5 |

| Width of cut ae (mm) | 3 | 3 |

| Coolant | Air blast | Air blast |