MillQuadFeed15 – Duplex Stainless Frame – U type inserts

IMPROVE TOOL LIFE

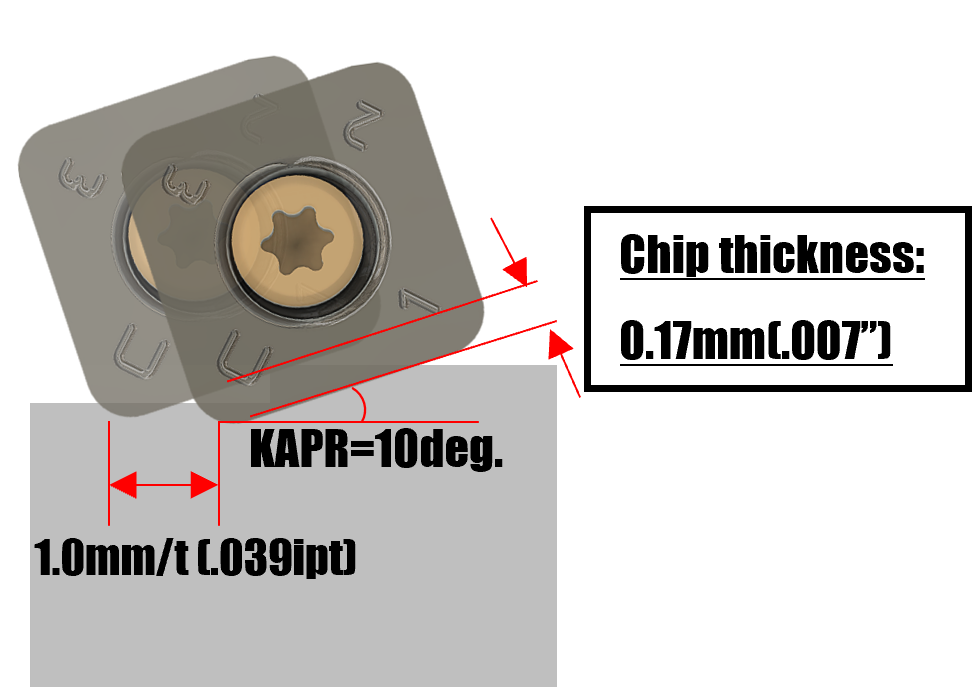

In a roughing test of a large curved plate , the competitor’s tool could not cut because cutting resistance was too high. Tungaloy proposed MillQuadFeed. With its small entry angle, it made thin chips and directed cutting force to the spindle, reducing chatter and edge breakage. As a result, six passes of roughing were completed stably. Tool life was extended three times compared to the competitor, reducing tool changes and setup loss.

Share

| Industry | Engineering |

|---|---|

| Component | Frame |

| Material ISO code |

|

| Work material | SUS821L1 |

| Machine(spindle type) | Horizontal Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | High feed milling |

| Product name | MillQuadFeed |

| TSR No. | 5358M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TXSW15J125B38.1R07 | Round-insert milling cutter |

| Number of teeth | 7 | 12 |

| Cutting diameter | 100 (3.93") | 100 (3.93") |

| Overhang (mm) | 168 (6.61") | 168 (6.61") |

| Insert | SWMT1506UER-MM | Round-insert |

| Number of cutting edges | 4 | 12 |

| Grade | AH3135 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 170 (558 sfm) | 170 (558 sfm) |

| Feed per tooth f/z (mm/t) | 0.82 (.032 ipt) | 0.5 (.019 ipt) |

| Feed speed Vf (mm/min) | 2,485 (97.8 ipm) | 2,706 (106.5 ipm) |

| Depth of cut ap (mm) | 1.0 (.039") | 1.0 (.039") |

| Width of cut ae (mm) | 80 (3.15") | 80 (3.15") |

| Coolant | Dry | Dry |