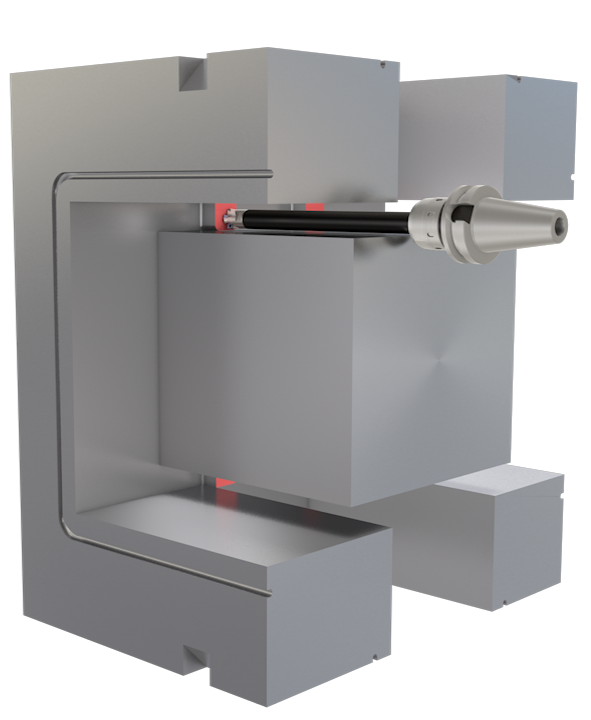

MillQuadFeed09 – Mold – Modular head

IMPROVED MACHINING TIME

The current machining process relied on the EDM (Electrical Discharge Machining) method, which posed the challenge of extremely long machining times.

To address this issue, the MillQuadFeed-UER, featuring a low entry angle, was proposed.

The low entry angle allowed axial cutting forces to act in the spindle direction, effectively reducing chatter even in cases of extremely long tool overhangs.

This significantly improved productivity and successfully reduced machining time by 90%.

Share

| Industry | Die & Mold |

|---|---|

| Component | Die block |

| Material ISO code |

|

| Work material | SKD61 |

| Material hardness | 30HRC |

| Machine(spindle type) | Horizontal Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | High feed milling |

| Product name | MillQuadFeed |

| TSR No. | 5102M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | HXSW09M032M16R04 | Electrical Discharge Machining |

| Number of teeth | 4 | - |

| Cutting diameter | 32 (1.26") | - |

| Overhang (mm) | 370(14.6" , L/D=11) | - |

| Insert | SWMT0904UER-MM | - |

| Number of cutting edges | 4 | - |

| Grade | AH3135 | - |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 50 (164sfm) | - |

| Feed per tooth f/z (mm/t) | 0.75 (.030ipt) | - |

| Feed speed Vf (mm/min) | 1,492 (58.7ipm) | - |

| Depth of cut ap (mm) | 0.2 (.008") | - |

| Width of cut ae (mm) | <32 (<1.26") | - |

| Coolant | Dry | - |