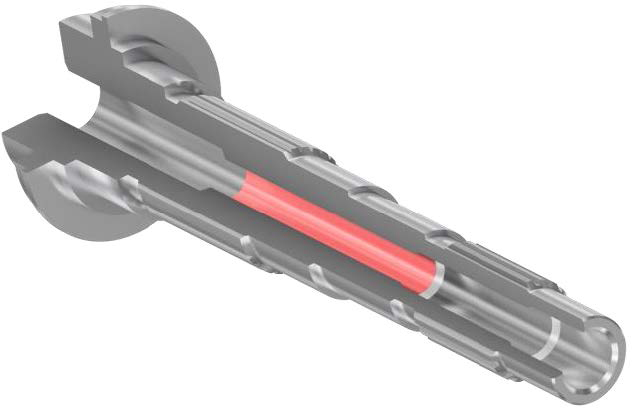

ReamMeister – Rotor Shaft – AH725

IMPROVED PRODUCTIVITY & TOOL LIFE

Thanks to wear-resistant AH725 PVD grade, combined with precision internal coolant delivery system, ReamMeister prevented rapid edge wear progression and eliminated built-up edge, providing secure hole diameters and 8 times tool life increase while doubling the productivity.

Share

| Industry | Automotive |

|---|---|

| Component | Rotor shaft |

| Material ISO code |

|

| Work material | 20CrS4 |

| Machine(spindle type) | Vertical Machining Center Small(#30,HSK40) |

| Tool family | Holemaking |

| Tool category | Reaming |

| Product name | ReamMeister |

| TSR No. | 1739D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TRM-T7-R20-5 | Solid carbide reamer |

| Head | tailored |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 16.09 | 16.09 |

| Hole tolerance grade | 16.09+-0.01 | 16.09+-0.01 |

| Pilot hole diameter (mm) | 15.9 | 15.9 |

| Surface quality required Ra (μm) | Rz 12.5 | Rz 12.5 |

| Hole depth H (mm) | 58 | 58 |

| Cutting speed V/c (m/min) | 80 | 60 |

| Feed f (mm/rev) | 0.6 | 0.4 |

| Coolant | Internal supply | Internal supply |