ReamMeister – Gear Counter Drive – AH725

IMPROVED PRODUCTIVITY & TOOL LIFE

ReamMeister eliminated vibration while providing process security and good surface quality at increased cutting parameters thanks to its tool stability ensured by secure tool support with the reamer margins. Furthermore, ReamMeister significantly reduced the machining time from 46 to 5(!!) seconds per part. Tool life was increased by over 20 times combined with premium surface quality. Significant improvements of machining efficiency and tool failures outbalanced initial increase in tool investments, thus allowing the customer to boost productivity.

Share

| Industry | Automotive |

|---|---|

| Component | Gear Counter Drive |

| Material ISO code |

|

| Work material | 18CrNiMo7-6 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Holemaking |

| Tool category | Reaming |

| Product name | ReamMeister |

| TSR No. | 1699D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

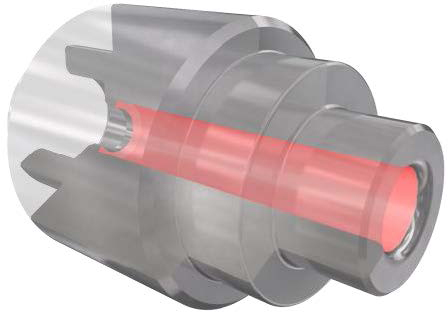

| Body | TRM-T8-R20-5 | Anti-vibration boring bar |

| Head | Special (ø20.050, z=8) | Positive ISO insert,2 corners |

| Grade | AH725 | PVD, P10 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 20.05 | 20.05 |

| Hole tolerance grade | ±0.05 | ±0.05 |

| Pilot hole diameter (mm) | 19.8 | 19 |

| Surface quality required Ra (μm) | 1.6 (μm) | 1.6 (μm) |

| Hole depth H (mm) | 100 | 100 |

| Cutting speed V/c (m/min) | 170 | 170 |

| Feed f (mm/rev) | 0.5 | 0.08 |

| Coolant | Internal supply | Internal supply |