ReamMeister – Diff Case – MTWMB

IMPROVED PRODUCTIVITY & TOOL LIFE

ReamMeister enabled precise and effective coolant delivery to the cutting points. In addition, wear- resistant MTWMB grade helped reduce development of wear and B.U.E., allowing long and stable tool life at increased cutting parameters, providing 15 times higher productivity and 7.5 times tool life increase.

Share

| Industry | Automotive |

|---|---|

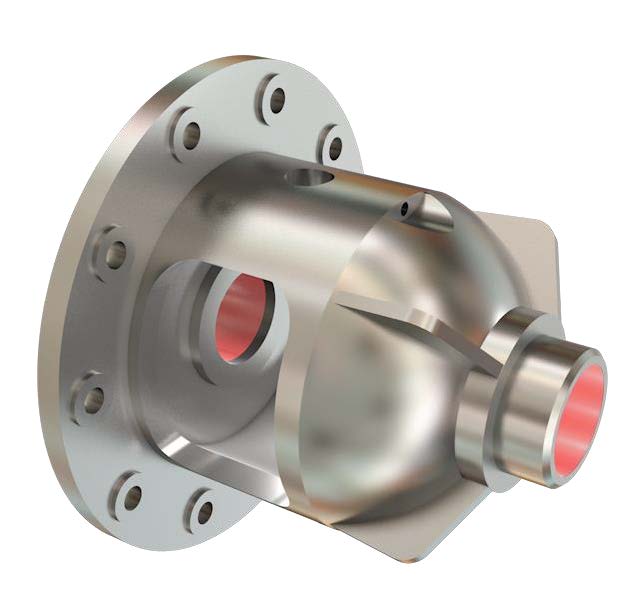

| Component | Differential case |

| Material ISO code |

|

| Work material | FCD600 |

| Machine(spindle type) | Horizontal Machining Center Middle(#40,HSK63) |

| Tool family | Holemaking |

| Tool category | Reaming |

| Product name | ReamMeister |

| TSR No. | 1738D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TRM-T9-R25-1.5 | Head exchangeable |

| Head | HRM-30.000-BL-T9 | ø30 mm, z=8 |

| Grade | MTWMB (tailored) | PVD, K20 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 30 | 30 |

| Hole tolerance grade | H8 | H8 |

| Pilot hole diameter (mm) | 29.8 | 29.8 |

| Surface quality required Ra (μm) | Rz 6.3 | Rz 6.3 |

| Hole depth H (mm) | 30 | 30 |

| Cutting speed V/c (m/min) | 150 | 63 |

| Feed f (mm/rev) | 1.25 | 0.2 |

| Coolant | Internal supply | Internal supply |