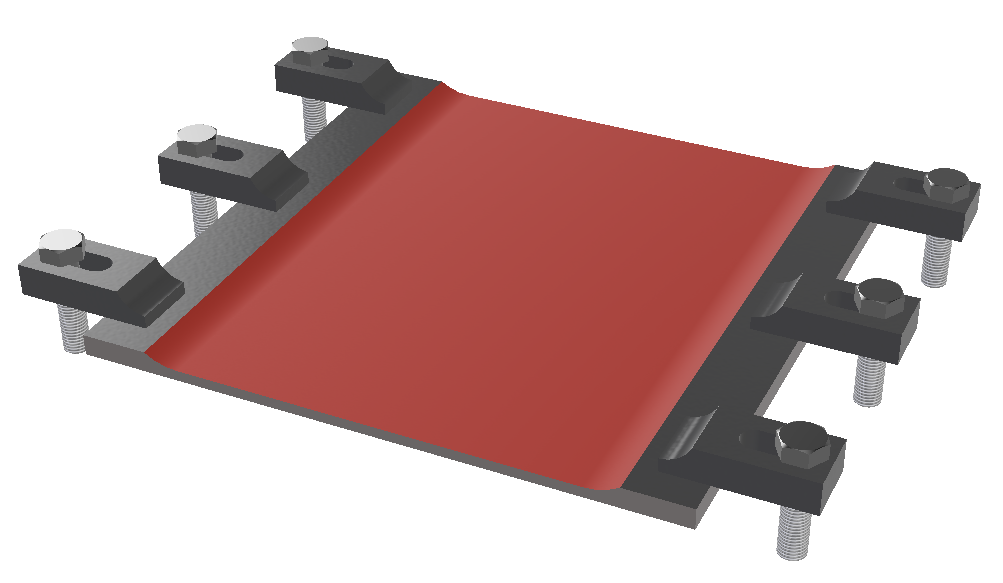

MillQuadFeed15 – Plate – U type inserts

IMPROVE TOOL LIFE & PRODUCTIVITY

In the process of reducing the thickness of SUS410HP plate from 16 mm to 8 mm using a competitor’s tool, low clamping rigidity and high cutting noise led to poor machining stability. To address this issue, the MillQuadFeed with a low-approach-angle U-type insert was proposed. It enabled low-resistance machining by generating thin chips and offering high edge strength. Stable one-pass machining was achieved, and seven consecutive workpieces were processed without any issues. Tool life improved to approximately seven times that of the previous tool.

Share

| Industry | Engineering |

|---|---|

| Component | Plate |

| Material ISO code |

|

| Work material | SUS410HP |

| Material hardness | 40 HRC |

| Machine(spindle type) | Vertical Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | High feed milling |

| Product name | MillQuadFeed |

| TSR No. | 5239M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TXSW15J125B38.1R07 | High feed cutter |

| Number of teeth | 7 | 6 |

| Cutting diameter | 125 | 125 |

| Insert | SWMT1506UER-MM | Positive 4-corner insert |

| Number of cutting edges | 4 | 4 |

| Grade | AH3135 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 140 | 103 |

| Feed per tooth f/z (mm/t) | 0.8 | 1.2 |

| Feed speed Vf (mm/min) | 1,996 | 1,888 |

| Depth of cut ap (mm) | 0.73 | 0.73 |

| Width of cut ae (mm) | 100 | 100 |

| Coolant | Wet ( external ) | Wet ( external ) |