MillQuadFeed09 – Machine tool components – U type inserts

IMPROVE PRODUCTIVITY

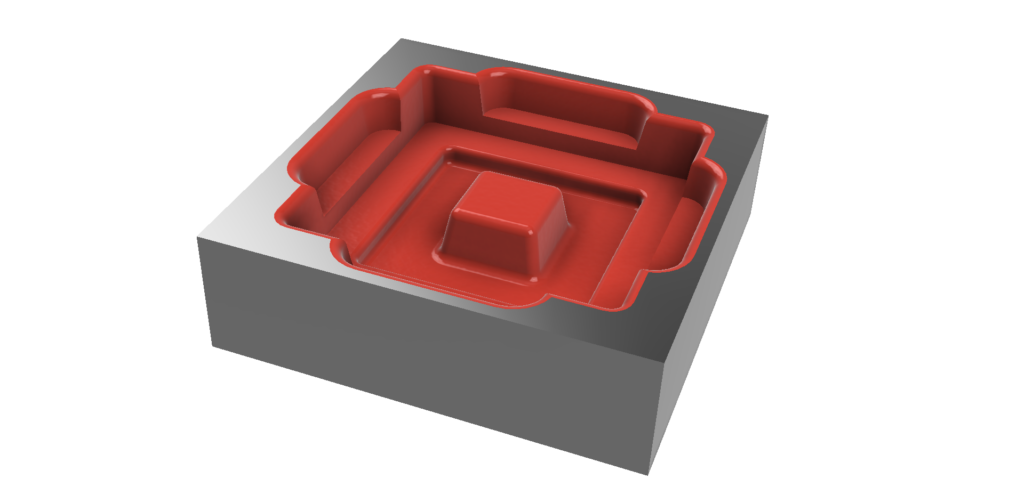

In pocket machining of machine tool components, chatter occurred with a competitor’s modular cutter. Although a solid carbide shank was used, the long overhang (L/D = 5) led to insufficient rigidity. To address this, we proposed UER-type inserts with a low approach angle for improved chatter suppression. As a result, chatter was eliminated and machining efficiency increased by seven times, significantly enhancing productivity through stable and high-efficiency machining.

Share

| Industry | Engineering |

|---|---|

| Component | Frame |

| Material ISO code |

|

| Work material | FC300 |

| Machine(spindle type) | Vertical Machining Center Middle(#40,HSK63) |

| Tool family | Milling |

| Tool category | High feed milling |

| Product name | MillQuadFeed |

| TSR No. | 5238M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | HXSW09M025M12R03 | Shoulder cutter |

| Number of teeth | 3 | 2 |

| Cutting diameter | 25 | 26 |

| Overhang (mm) | 130 | 130 |

| Insert | SWMT0904UER-MM | Square insert |

| Number of cutting edges | 4 | 2 |

| Grade | AH120 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 150 | 156 |

| Feed per tooth f/z (mm/t) | 0.7 | 0.15 |

| Feed speed Vf (mm/min) | 4,011 | 573 |

| Depth of cut ap (mm) | 0.8 | 0.8 |

| Width of cut ae (mm) | 5 | 5 |

| Coolant | Wet ( internal ) | Wet ( internal ) |