TungCut – Roll – BXA10

IMPROVED PRODUCTIVITY AND TOOL LIFE

Ceramic inserts were previously used for the outer diameter profiling of rolls. However, since ceramic inserts lack chip breakers, chip evacuation was unstable. By switching to CTR-type inserts with chip breakers, chip control was significantly improved.

As a result, even when the cutting speed was increased by more than two times, the TungCut CTR-type CBN insert achieved more than 4 times longer tool life. This led to a significant improvement in both machining efficiency and tool life.

Share

| Industry | Engineering |

|---|---|

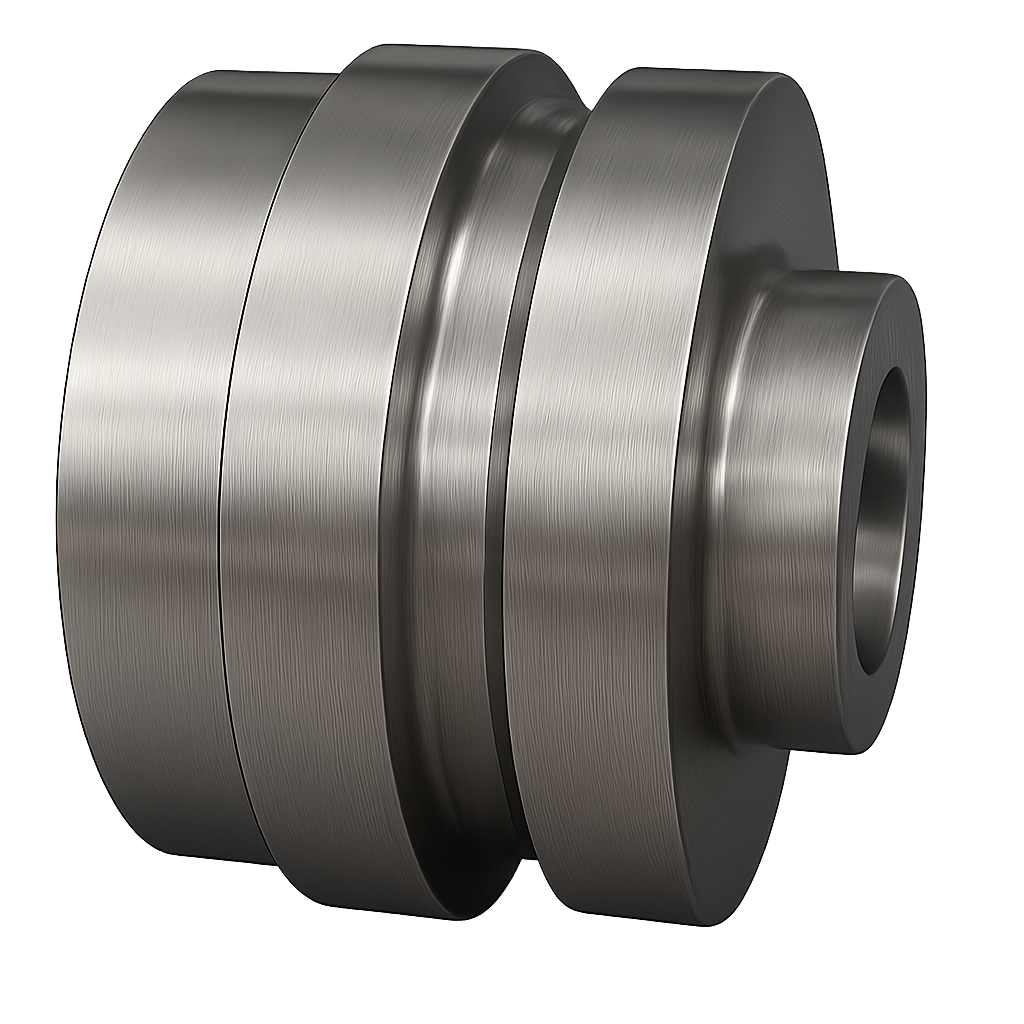

| Component | Roll |

| Material ISO code |

|

| Work material | SKD11/1.2379 |

| Material hardness | 62~64HRC |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External grooving & turning |

| Product name | TungCut |

| TSR No. | 5209T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | CTER2525-3T12 | 25x25 shank |

| Insert | STR300-HP | Ceramic insert |

| Edges par insert | 1 | 1 |

| Grade | BXA10 | Ceramic |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 14 | 3 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 180 | 80 |

| Feed f (mm/rev) | 0.08 | 0.08 |

| Depth of cut ap (mm) | 0.05 | 0.05 |

| Coolant | Wet(External) | Wet(External) |