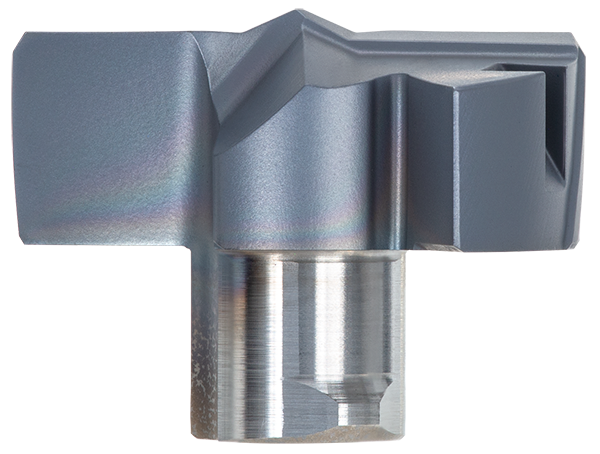

DrillMeister – Valve connecter- DMF

IMPROVE TOOL LIFE

The drilling process was previously carried out using a U-Drill, but the short tool life was a bottleneck in the process due to machine down time. By adopting the DrillMeister DMF head, high feed processing has been achieved, significantly improving tool life to 3.4 times longer than before and avhide reduce machine down time.

Share

| Industry | Engineering |

|---|---|

| Component | Valve part |

| Material ISO code |

|

| Work material | X2CrNiMoN22-5-3 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillMeister |

| TSR No. | 5153H |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TID210F32-1.5 | U-Drill 2xD |

| Head | DMF210 AH9130 | 4 cutting edges positive insert |

| Grade | AH9130 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 51 | 15 |

| Number of workpieces (pcs/insert) | 1700 | 500 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 21 | 21 |

| Hole tolerance grade | IT9 | IT11 |

| Hole depth H (mm) | 30 | 30 |

| Cutting speed V/c (m/min) | 33 | 119 |

| Feed f (mm/rev) | 0.2 | 0.05 |

| Feed speed Vf (mm/min) | 100 | 90 |