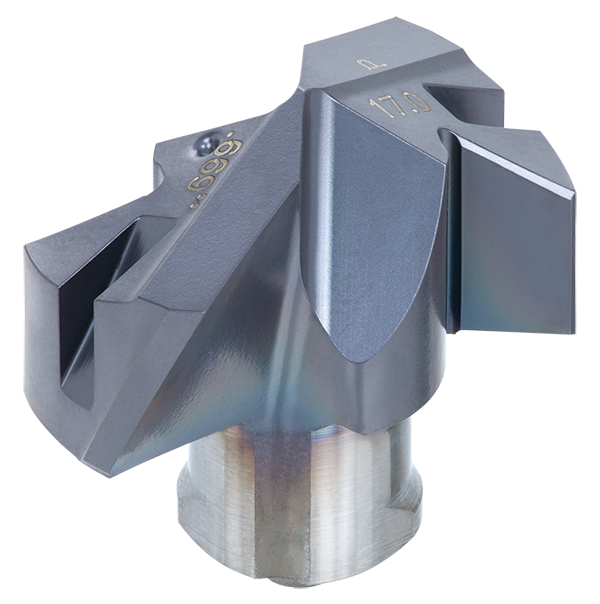

DrillMeister – Secondary Shaft – DMP AH9130

IMPROVE TOOL LIFE

The goal was to stably machine 2,000 units, but conventional tools had a tool life of approximately 1,700 units(91m). By combining the DrillMeister DMP with the latest AH9130 coating, stable machining of 3,000 units(161m) has become possible. This improvement increased tool life by 1.76 times, significantly reducing tool costs.

Share

| Industry | Automotive |

|---|---|

| Component | Secondary pulley shaft |

| Material ISO code |

|

| Work material | 16MnCr5 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillMeister |

| TSR No. | 5152H |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TID150F20-3 | Head exchangable drill 3xD |

| Head | DMP152 AH9130 | Drill head 140deg |

| Grade | AH9130 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 161 | 91 |

| Number of workpieces (pcs/insert) | 3000 | 1700 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 15.2 | 15.2 |

| Hole tolerance grade | IT9 | IT9 |

| Hole depth H (mm) | 54 | 54 |

| Cutting speed V/c (m/min) | 86 | 86 |

| Feed f (mm/rev) | 0.35 | 0.35 |

| Feed speed Vf (mm/min) | 630 | 630 |

| Coolant | Internal coolant | Internal coolant |