DrillMeister – Spindle – AH9130

IMPROVED PRODUCTIVITY

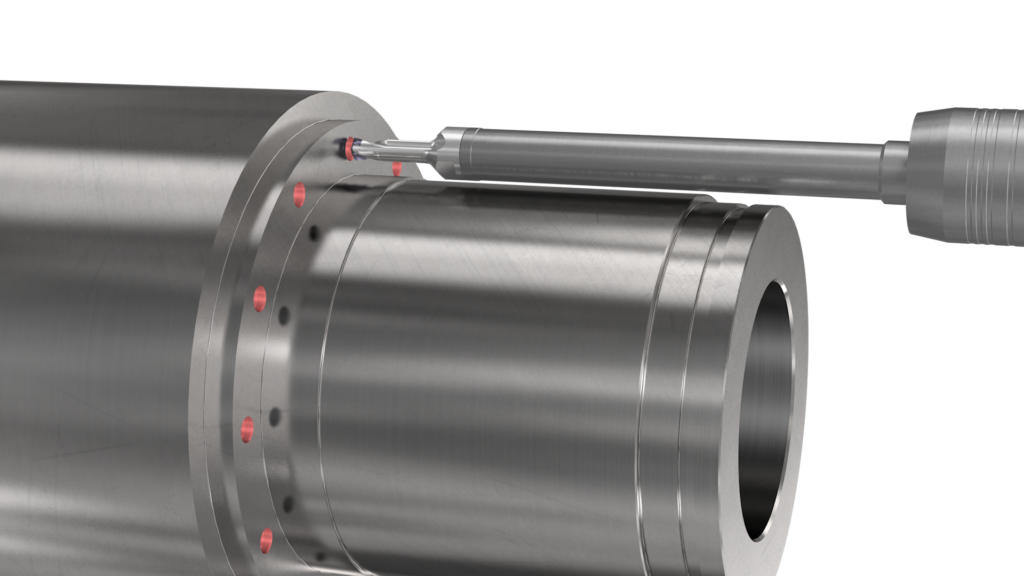

For spindle machining on machine tools, it was necessary to perform long protrusion hole machining due to tool interference.

The conventional product used was an HSS 20xD long drill, but the long protrusion length caused instability during machining, so low cutting conditions were used.

To improve productivity, we combined the DrillMeister modular body with a 200mm carbide shank, enhancing tool rigidity while avoiding interference.

As a result, the machining process became stable, achieving a tenfold increase in machining efficiency.

Share

| Industry | Machine Tool Builders |

|---|---|

| Component | Spindle |

| Material ISO code |

|

| Work material | S45C/C45 |

| Machine(spindle type) | Multi-Tasking Machine |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillMeister |

| TSR No. | 5035D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TID085M10-3 | Solid drill |

| Head | DMC085 | |

| Grade | AH9130 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 8.5 | 8.5 |

| Hole depth H (mm) | 20 | 20 |

| Cutting speed V/c (m/min) | 100 | 20 |

| Feed f (mm/rev) | 0.2 | 0.1 |

| Feed speed Vf (mm/min) | 749 | 74 |

| Coolant | Internal | Internal |