AddDoFeed – Semiconductor part – SUS304

IMPROVED PRODUCTIVITY

The current solid end mill had unstable tool life, frequent sudden breakages, and high tool costs.

In response, we proposed the AddDoFeed. By utilizing low-depth, high-feed machining, processing efficiency was improved by 2.3 times. Additionally, tool life became stable, enhancing machining reliability.

Share

| Industry | Engineering |

|---|---|

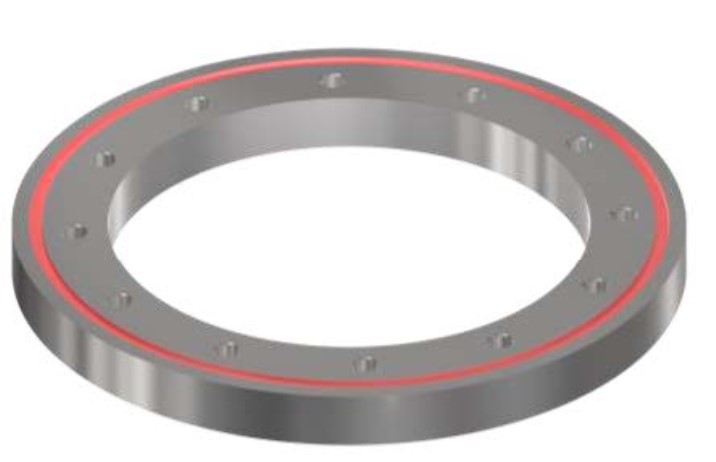

| Component | Semiconductor part |

| Material ISO code |

|

| Work material | SUS304/X5CrNi18-10 |

| Machine(spindle type) | Vertical Machining Center Middle(#40,HSK63) |

| Tool family | Milling |

| Tool category | Pocketing |

| Product name | AddDoFeed |

| TSR No. | 5070M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | EXN02R010M10.0-02 | Solid Endmill |

| Number of teeth | 2 | 4 |

| Cutting diameter | 10 | 12 |

| Overhang (mm) | 130 | 130 |

| Insert | LNMU0202ZER-MM | |

| Number of cutting edges | 4 | 1 |

| Grade | AH130 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 130 | 50 |

| Feed per tooth f/z (mm/t) | 0.42 | 0.03 |

| Feed speed Vf (mm/min) | 3476 | 191 |

| Depth of cut ap (mm) | 0.4 | 5 |

| Width of cut ae (mm) | 8 | 5 |

| Coolant | Wet(Internal) | Wet(External) |