MillQuadFeed15 – Construction Part – AH3135

IMPROVED PRODUCTIVITY

High productivity

- The customer was using a flat shaped insert to avoid a fracture of cutting edge doe to machining of interrupted casting face. But it is not increase feeds because of machine vibration. MillQuadFeed’s insert has rake angle, it prevent machine vibration and it canincrease feed. As a result, MillQuadFeed achieve 4.2 times MRR against competitor by increase the cutting speed and feed rate. Also thanks to the toughened cutting edge andgrade, the fracture did not occurred.

Share

| Industry | Heavy |

|---|---|

| Component | Construction Part |

| Material ISO code |

|

| Work material | FC250 |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | MillQuadFeed |

| TSR No. | 568M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

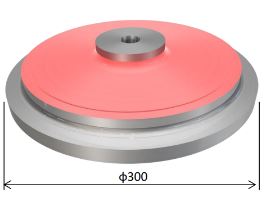

| Body | TXSW15M063B22.0R04 | High feed cutter |

| Effective number of teeth | 4 | 3 |

| Cutting diameter | 63 | 63 |

| Insert | SWMT1506ZER-MJ | W type positive insert |

| Number of cutting edges | 4 | 3 |

| Grade | AH3135 | PVD (P15) |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 200 | 120 |

| Feed per tooth f/z (mm/t) | 1.5 | 0.8 |

| Feed speed Vf (mm/min) | 6000 | 1440 |

| Depth of cut ap (mm) | 1 | 1 |

| Width of cut ae (mm) | 30 | 30 |

| Coolant | Dry | Dry |