GT9530 – Oil Hydraulic Equipment Parts – GT9530

IMPROVED TOOL LIFE

Stable machining & extended tool life

- In external turning of oil hydraulic equipment parts, the competitor is unable to provide stable machining because of chipping, and its tool life ends due to vibration with increased flank wear. The combination of GT9530 & TSF chipbreaker with excellent wear and chipping resistance extends tool life by 1.6 times compared to the competitor.

Share

| Industry | Engineering |

|---|---|

| Component | Oil Hydraulic Equipment Parts |

| Material ISO code |

|

| Work material | 34CrMo4 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | GT9530 |

| TSR No. | 481T |

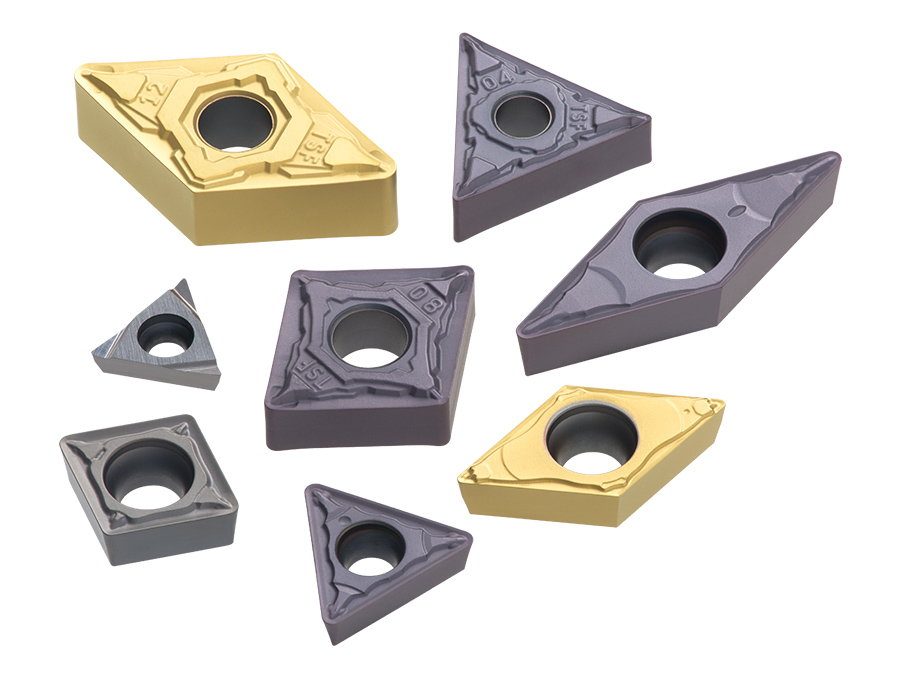

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | DVLNR2020K16 | DVLNR2020K16 |

| Insert | VNMG160404-TSF | VNMG160404-Finish chip breaker |

| Grade | GT9530 | Coated cermet |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 500 | 300 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 165 | 165 |

| Feed f (mm/rev) | 0.15 | 0.15 |

| Depth of cut ap (mm) | 0.15 | 0.15 |

| Coolant | Wet | Wet |