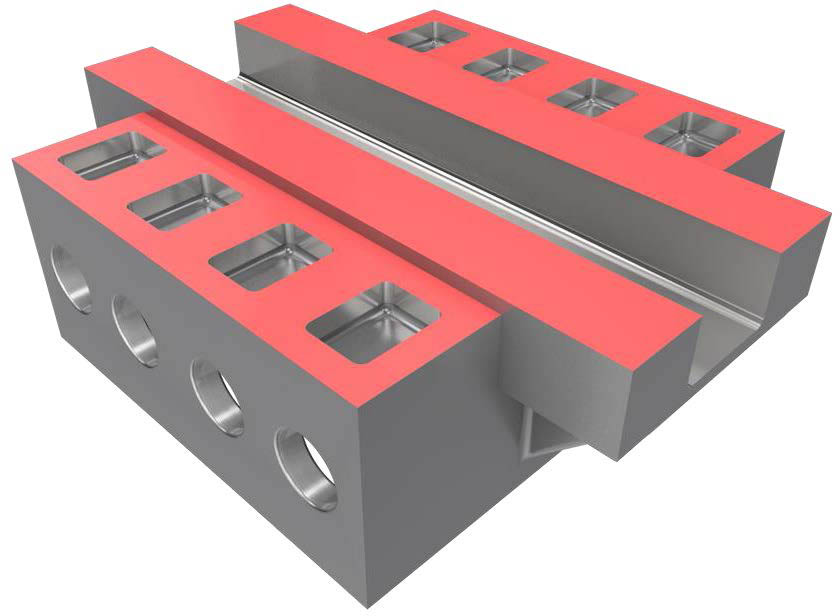

DoOcto – Machine Base – T1215

IMPROVED TOOL LIFE AND SAVED POWER CONSUMPTION

Long tool life

- T1215 grade with thick Al2O3 layer achieves more stable and longer tool life although the number of pockets is smaller than the competitor. Its tough cutting edge absorbs impact during machining without fracture in spite of 160% of the competitor’s feed rate.

Low torque and power

- Reducing the number of pockets decreases the torque requirements and the power consumption by 15%

Share

| Industry | Engineering |

|---|---|

| Component | Machine Base |

| Material ISO code |

|

| Work material | DIN GG25 |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | DoOcto |

| TSR No. | 455M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TAN07R160M50.8-10 | Face mill cutter |

| Effective number of teeth | 16 | 14 |

| Cutting diameter | 160 | 160 |

| Insert | ONMU0705ANPN-MJ | Hexagonal type negative insert |

| Number of cutting edges | 16 | 14 |

| Grade | T1215 | CVD(K20) |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 200 | 200 |

| Feed per tooth f/z (mm/t) | 0.38 | 0.24 |

| Feed speed Vf (mm/min) | 1512 | 1512 |

| Depth of cut ap (mm) | 2 | 2 |

| Width of cut ae (mm) | 120 | 120 |

| Coolant | Dry | Dry |