TetraForce-Cut – Clutch Parts – AH725

IMPROVED TOOL LIFE

High productivity

– The current tool was inferior in surface quality because of chip scratching, that required 3 pass in total including finishing. On the other hand, TetraForce-Cut with unique three-dimensional chipbreaker achieved outstanding chip control and much better surface only with 1 pass! Thus, TetraForce-Cut successfully shortened machining time by 1 / 3 compared to the current item.

Longer tool life

-TetraForce-Cut with AH725 has high wear resistance. As a result, 1.7 times longer tool life were achieved against competitors’s one!

Share

| Industry | Automotive |

|---|---|

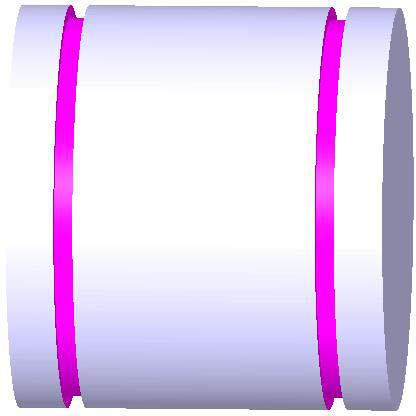

| Component | Clutch Parts |

| Material ISO code |

|

| Work material | AISI1043 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | TetraForce-Cut |

| TSR No. | 354T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | STCL2020-27 | 20x20 shank |

| Insert | TCS27-200-020 | 3 corner insert |

| Edges par insert | 4 | 3 |

| Cutting width | 2 | 1.5 |

| Grade | AH725 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 422 | 250 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 120 | 120 |

| Feed f (mm/rev) | 0.05 | 0.05 |

| Depth (mm) | 1.3 | 1.3 |

| Coolant | Wet | Wet |