TungAluMill – Jig Fixture – TH10

PRODUCTIVITY

Productivity –

Higher number of pockets in the tool compared to competitor allows increasing the productivity for the customer by 1.5 times.

Tool advantages –

TungAluMill enables further improvement in productivity than competitor due to its high allowable maximum RPM as well as large ramping angle.

Share

| Industry | Automotive |

|---|---|

| Component | Jig |

| Material ISO code |

|

| Work material | 6061 |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Milling |

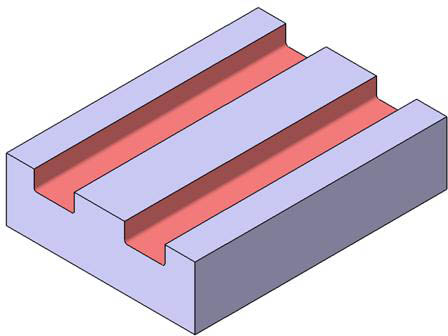

| Tool category | Slot milling |

| Product name | TungAluMill |

| TSR No. | 326M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | EPV16R032M32.0-03 | ø32 - z = 2 |

| Cutting diameter | 32 | 32 |

| Insert | XVCT160508R-AJ | 2 corner positive insert |

| Number of cutting edges | 2 | 2 |

| Grade | TH10 | Non coated carbide |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 1005 | 1005 |

| Feed per tooth f/z (mm/t) | 0.2 | 0.2 |

| Feed speed Vf (mm/min) | 5998 | 5998 |

| Depth of cut ap (mm) | 2 | 2 |

| Width of cut ae (mm) | 32 | 32 |

| Coolant | Dry | Dry |