TungQuad – Shaft – AH725

IMPROVED PRODUCTIVITY

Double productivity

- Low cutting force insert enables to machine the work piece in higher cutting condition without chattering.

Low tool cost

- In comparison with solid carbide endmill, indexable solution reduces tool cost by half.

Share

| Industry | Automotive |

|---|---|

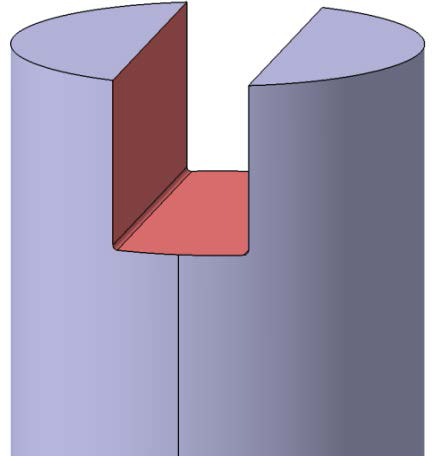

| Component | Shaft |

| Material ISO code |

|

| Work material | Mild Steel |

| Machine(spindle type) | Machining Center |

| Tool family | Milling |

| Tool category | Slot milling |

| Product name | TungQuad |

| TSR No. | 181M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | EPD05R012M12.0-02 | Solid carbide end mill |

| Effective number of teeth | 2 | 6 |

| Cutting diameter | 12 | 12 |

| Insert | SDMT050204PN MJ | |

| Number of cutting edges | 4 | 1 |

| Grade | AH725 | TiAlN |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 158 | 98 |

| Feed per tooth f/z (mm/t) | 0.07 | 0.03 |

| Feed speed Vf (mm/min) | 600 | 500 |

| Depth of cut ap (mm) | 1 | 0.7 |

| Width of cut ae (mm) | 12 | 12 |

| Coolant | Wet (water soluble) | Wet (water soluble) |