TungAluMill – Machine Part – TH10

IMPROVED TOOL LIFE

Stable wear on the Insert

– After machining the complete part at the customer, the competitor insert had large wear and also uneven damage conditions of all the inserts. Which was a concern for the customer. TungAluMill showed very low and even wear on all inserts thus providing high reliability in processing the component. TungAluMill inserts provide long tool life due to specially designed rake and relief angle.

Share

| Industry | Engineering |

|---|---|

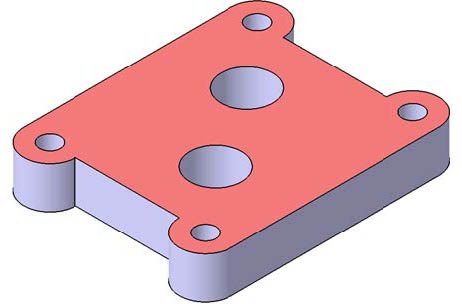

| Component | Machine Parts |

| Material ISO code |

|

| Work material | 6061 |

| Machine(spindle type) | Horizontal Machining Center |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | TungAluMill |

| TSR No. | 325M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TPV16R050M22.0E04 | Shoulder milling cutter |

| Effective number of teeth | 4 | 4 |

| Cutting diameter | 50 | 50 |

| Insert | XVCT160504R-AJ | 2 corner positive insert |

| Number of cutting edges | 2 | 2 |

| Grade | TH10 | No coated carbide |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 471 | 471 |

| Feed per tooth f/z (mm/t) | 0.08 | 0.08 |

| Feed speed Vf (mm/min) | 960 | 960 |

| Depth of cut ap (mm) | 3 | 3 |

| Width of cut ae (mm) | 30 | 30 |

| Coolant | Wet (Internal) | Wet (Internal) |