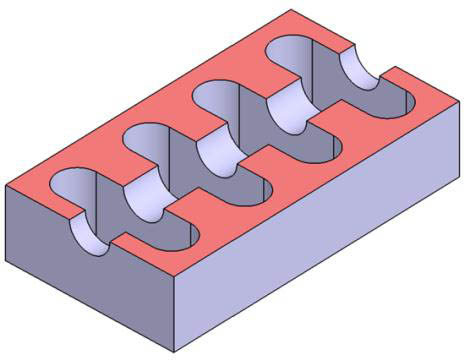

DoPent – Truck Engine Crankcase – T3225

IMPROVED PRODUCTIVITY & TOOL LIFE

Higher productivity

- Improved Productivity & Tool Life in Machining of Crankcase Even though clamping rigidity of the workpiece is low, DoPent’s sharp cutting edge and 70 degrees approach angle enable stable machining without chattering. Productivity increases by 190%.

Longer tool life

- T3235 provides a good wear resistance because of its thick CVD coating, leading to doubled tool life.

Share

| Industry | Automotive |

|---|---|

| Component | Truck Engine Crankcase |

| Material ISO code |

|

| Work material | Alloyed Cast Iron |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | DoPent |

| TSR No. | 304M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TEN09R125M38.1-06 | Shoulder milling cutter |

| Effective number of teeth | 6 | 6 |

| Cutting diameter | 125 | 125 |

| Insert | PNCU0905GNER-MJ | W type negative insert |

| Number of cutting edges | 10 | 6 |

| Grade | T3225 | CVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 196 | 196 |

| Feed per tooth f/z (mm/t) | 0.25 | 0.1 |

| Feed speed Vf (mm/min) | 749 | 399 |

| Depth of cut ap (mm) | 2 | 2 |

| Width of cut ae (mm) | 100 | 100 |

| Coolant | Dry | Dry |