DoPent – Point rail – T3130

IMPROVED TOOL LIFE

- Wear resistance can be improved by changing the T3130, wear is reduced dramatically.

- T3130 was controled chipping and crater wear, and it was not observed chipping.

Share

| Industry | Heavy |

|---|---|

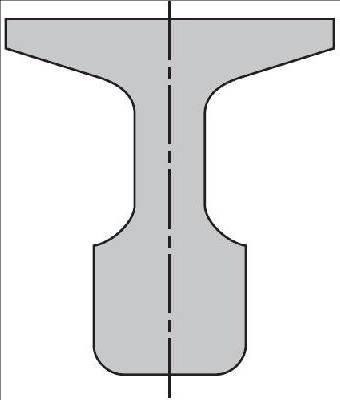

| Component | Point rail |

| Material ISO code |

|

| Work material | PR80S |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | DoPent |

| TSR No. | 164M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TEN09R200M47.6-08 | TEN09R200M47.6-08 |

| Effective number of teeth | 8 | 8 |

| Cutting diameter | 200 | 200 |

| Insert | PNCU0905GNER-MJ | PNCU0905GNER-MJ |

| Grade | T3130 (CVD) | AH120 (PVD) |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 150 | 150 |

| Feed per tooth f/z (mm/t) | 0.28 | 0.28 |

| Feed speed Vf (mm/min) | 530 | 530 |

| Depth of cut ap (mm) | 3 | 3 |

| Width of cut ae (mm) | 145 | 145 |

| Coolant | Dry condition | Dry condition |