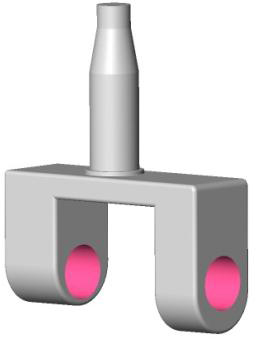

TungSix-Drill – Knuckle – AH9030

IMPROVED MACHINING STABILITY AND TOOL LIFE

ECO Operation

- Low spindle load and Low cutting noise compared to competitor due to low cutting forces and balanced design.

Insert wear

- Wear pattern is stable, hence all 6 cutting edges can be used.

Economical

- TungSix-Drill is more economical due to 1.5 times higher number of cutting edges.

Share

| Industry | Automotive |

|---|---|

| Component | Knuckle |

| Material ISO code |

|

| Work material | 42CrMo4 |

| Machine(spindle type) | Horizontal Machining Center Large(#50,HSK100) |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | TungSix-Drill |

| TSR No. | 151D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TDS500F40-3 | Indexable drill |

| Insert | WWMU13X512R-DJ | Square type insert |

| Grade | AH9030 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 30 | 20 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 50 | 50 |

| Hole depth H (mm) | 80 | 80 |

| Cutting speed V/c (m/min) | 160 | 160 |

| Feed f (mm/rev) | 0.11 | 0.11 |

| Feed speed Vf (mm/min) | 112 | 112 |

| Coolant | Water soluble(Internal) | Water soluble(Internal) |