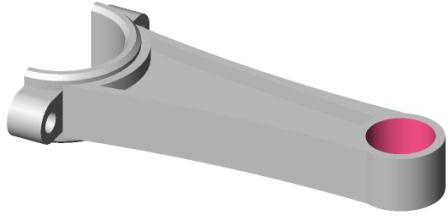

TungSix-Drill – Connecting Rod – AH9030

IMPROVED PRODUCTIVITY AND TOOL LIFE

- TungSix-Drill allows 1.3 times higher feed rate than the competitor, even when drilling into the concavity of forged part due to the tough cutting edges.

- AH9030 provides long tool life even when machining with external coolant supply because of the high oxidation resistance of coating layer.

- While competitor’s tool requires two kinds of inserts in one body, TungSix-Drill needs only ONE shape of insert. This simplifies inventory control.

Share

| Industry | Automotive |

|---|---|

| Component | Connecting Rod |

| Material ISO code |

|

| Work material | C55 |

| Machine(spindle type) | Vertical Machining Center Middle(#40,HSK63) |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | TungSix-Drill |

| TSR No. | 130D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TDS280F32-2 | Indexable drill |

| Insert | WWMU08X408R-DJ | Square type insert |

| Grade | AH9030 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 42.5 | 24 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 28 | 28 |

| Hole depth H (mm) | 30 | 30 |

| Cutting speed V/c (m/min) | 193 | 193 |

| Feed f (mm/rev) | 0.15 | 0.12 |

| Feed speed Vf (mm/min) | 329 | 263 |

| Coolant | Water soluble (External) | Water soluble (External) |